Vinyl Wet Areas

Key Considerations

- Falls

- Preparation

- Curing of screeds

- Installation and application

- Temporary protection

Design

Vinyl wet area design must consider:

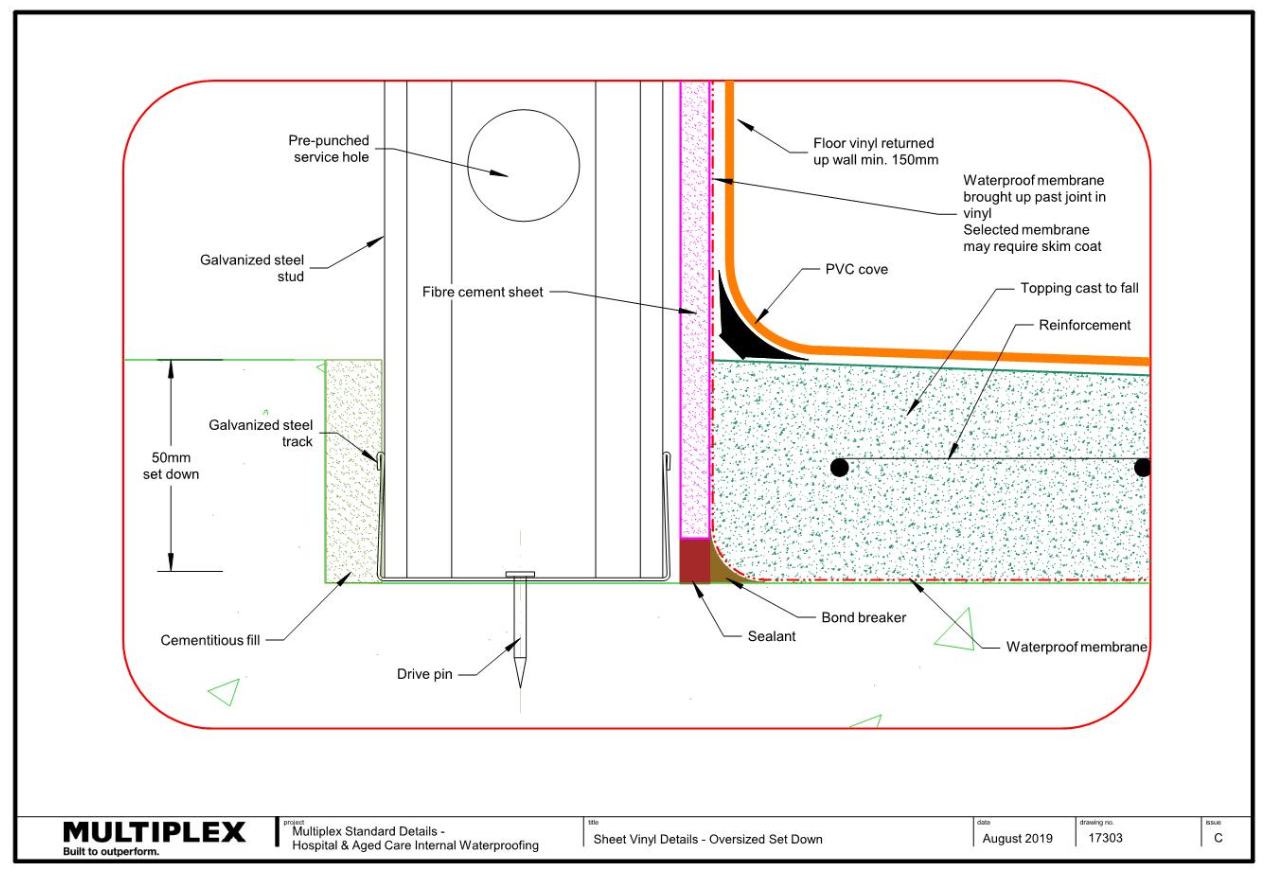

- Standard MPX 17300 series of drawings.

- Falls in the finished vinyl sheet are to be suitable for draining surface water without ponding.

- Falls to ensuite floors are to be 1:80 to 1:100

- Floor wastes located in alignment with the shower head connection point and 600 mm out from the wall.

- Floor wastes being stainless steel or chrome plated brass clamping type purpose made for sheet vinyl.

- Joins being placed away from shower head connection point in the least obtrusive location; preferably behind doors or aligned with the edge of the door frame.

- Floors laid in one piece if practicable.

- Seams, joins, and the like being fully welded and be watertight.

- Seams being true and parallel without gaps and peaking to provide an even and flush finish.

Toppings / Screeds

Toppings/screeds for vinyl floor must:

- Achieve a compressive strength of 20 MPa and tensile strength of 1.5 MPa. This can be achieved using sand-cement screed with polymer additives, or by using a Granolithic topping.

- Have falls in the finished vinyl sheet that can drain surface water without ponding. Where feasible, falls in shower areas must be 1:60 - 1:80, other areas 1:80 - 1:100. In no case is the fall be less than 1:100.

- Be installed with a vapour barrier.

Floor Wastes

Floor waste must be:

- Stainless steel or chrome plated brass clamping type, purpose-made for sheet vinyl.

- Cast into the slab, topping or screed.

Preparation

Material Storage

- Before laying, vinyl must be left on site in accordance with the timeframe nominated by the manufacturer in order to acclimatise.

- Se stored upright and out of direct sunlight.

Application

- Vinyl must be approved as per project sample submission (needs to be tested to AS 4858).

- Floor sheets must be laid first and returned up walls by not less than 150mm.

- Floor and wall junctions must be provided with a compatible pre-manufactured PVC cove with a radius of not less than 25mm.

- Welded joins must be placed outside the shower recess in the least obtrusive location; preferably behind doors or aligned with the edge of the door frame.

- Sheet joints must not be placed closer than 300mm from a floor waste.

- Butterfly joints to corners.

Protection

- Adequate temporary protection (i.e. plywood or MDF sheeting) must be put in place to ensure the finished vinyl is protected from damage.

- Do not use temporary protection that contains dies or colourants. Only raw board or clear plastic is permitted.

Multiplex Standard Details

17301 - Typical Ensuite Plan

17302 - Sheet Vinyl Details - Welded Wall Joint

17303 - Sheet Vinyl Details - Oversized Set Down

17304 - Sheet Vinyl Details - Section Through Door Opening, Slab With Set Down

17305 - Sheet Vinyl Details - Sheet Vinyl Details - Section Through Door Opening, Slab With Oversize Set Down

17306 - Sheet Vinyl Details - Side View of WC Pan

17307 - Sheet Vinyl Details - Detail From Drawing 17306

17308 - Sheet Vinyl Details - Section Through S.P.S. Floor Waste With Integral Leak Control Flange

17309 - Sheet Vinyl Details - Bath Tub Installation, General Arrangement Plan

17310 - Sheet Vinyl Details - Bath Tub Installation, Framing Plan

17311 - Sheet Vinyl Details - Bath Tub Installation, Detail 1 from 17310

17312 - Sheet Vinyl Details - Bath Tub Installation, Detail 2 from 17310

17313 - Sheet Vinyl Details - Bath Tub Installation, Longitudinal Section

17314 - Sheet Vinyl Details - Bath Tub Installation, Transverse Section

17315 - Sheet Vinyl Details - Bath Tub Installation, Detail 3 from 17313

17316 - Sheet Vinyl Details - Bath Tub Installation, Detail 3A from 17313

17317 - Sheet Vinyl Details - Bath Tub Installation, Detail 4 from 17314

17318 - Sheet Vinyl Details - Section Through 135 degrees Corner

Document Control

Version 3.1 December 2020

Major Update: Drawing No. 17318 is a new addition to MPX

Standard Detail.