Fire Resistant Door sets

Key Considerations

- Compartmentation Plans - Fire & Smoke

- Fire Resistance Level (FRL)

- Interface between framing and wall (i.e. plasterboard, masonry)

- Filling of frames

What is a fire resistant door set?

Fire resistant door set is tested as a complete assembly including:

- A steel or timber frame, and

- The door leaf or leaves, and

- All the hardware,

Fire resistant door sets:

- May be sliding or side hung.

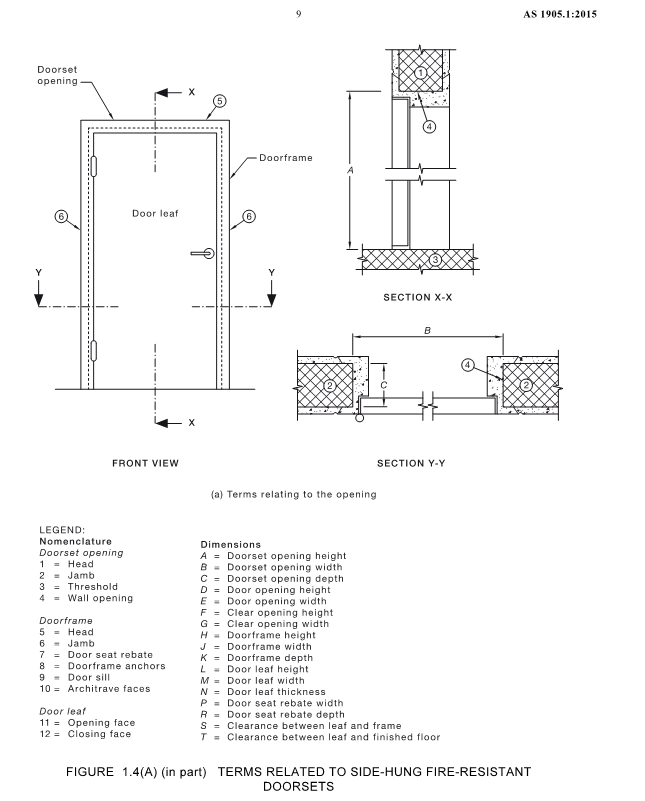

- Must be designed and manufactured to AS1905.1 for side hung doors.

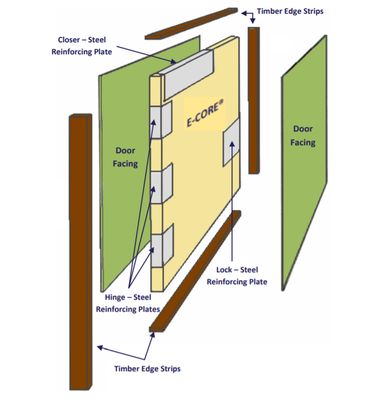

- Are generally made with a core of fire-resistant material which incorporates metal reinforcing plates at the fixing points of the hinges, door closer and latch. It has timber edge strips to all edges and is then sheeted both sides with facing sheets made of MDF, plywood and/or other materials.

Why is a fire resistant doorset required?

- To protect openings required in fire separating walls to enable access to other parts of the building and for safe egress.

- It is a critical as part of building fire protection system designed to reduce the spread of fire and smoke between separate compartments of a structure and to enable safe egress from a building or structure.

Installation

- Door sets used must be installed as per approved sample and supplied test report/evidence of suitability.

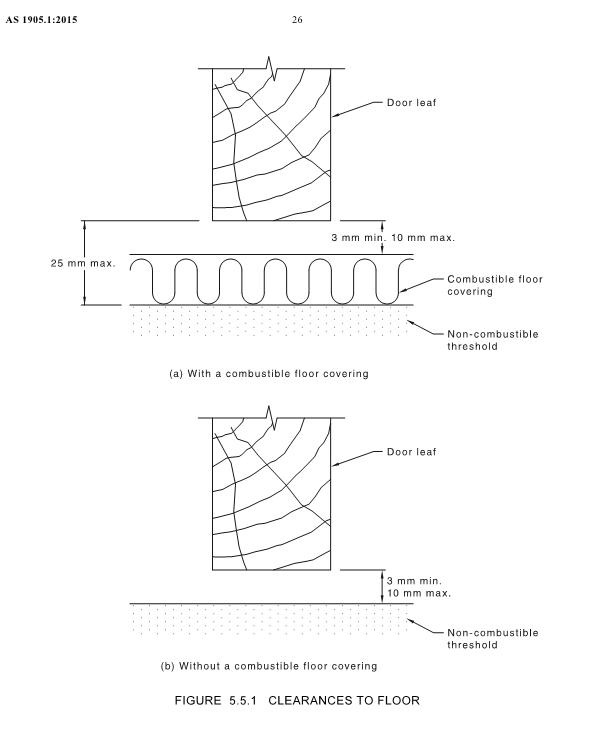

- Door leaf clearances must be as per Clause 5.5 of AS1905.1, i.e. a minimum of 3 mm to a maximum 10 mm gap at the bottom of the door leaf to the carpet or other floor finish.

- Sides and top must have gaps of an average of 3mm.

- Fill door frames as per tested specimen

- Frames must:

- When grouted, have no hollow sounds when tapped. (hollow sounds due to shrinkage of the fill may be acceptable)

- In plasterboard walls, filled with plasterboard strips, vermiculite plaster or plaster, but not a combination of the these.

- Fixings of the steel doorframes must be not greater than 300 mm in light weight and SpeedPanel walls and at 400 mm centres into masonry walls. Refer to the manufacturer’s literature to confirm other fixing requirements.

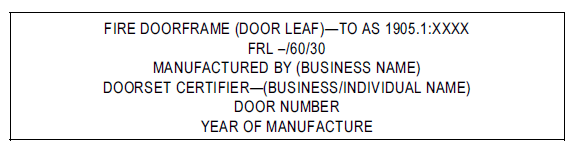

- Completed installations must be tagged strictly in accordance with AS1905 with metal tags a minimum size of 50 x 25 mm and nailed or riveted in place and include the following information:

- Number of the standard

- FRL

- Name of the manufacturer

- Name of the applicant (or sponsor)

- Name of the certifier/surveyor

- Year of manufacture

- Serial number (or doorset number)

- Lettering must be not less than 2 mm high and done by etching, embossing or stamping so that it is below or above the surface 0.5 mm.

- Tags must be installed at 1500 mm above floor level:

- To the door frame near the door leaf tag, screwed or rivetted,

- On side hung doors, fixed to the hinge stile, by nailing with flat head nails,

- On two leaf doorsets, fixed to both leaves on the hinge stile,

- On sliding doorsets, fixed to the trailing edge.

Document Control

June 2024 – General updates installation requirements