Speed Panel Service Shafts

Key Considerations

- Compartmentation Plans - Fire & Smoke

- Fire Resistance Level (FRL)

- Element Material FRL (i.e. wall, floor, ceiling)

- Service Material FRL (i.e. penetrating a compartment, FRL)

- Fire/smoke stopping system (as per MPX schedule)

Framing and Panels

Speedpanel shafts should be installed in accordance with the Speedpanel Shaft Wall Details

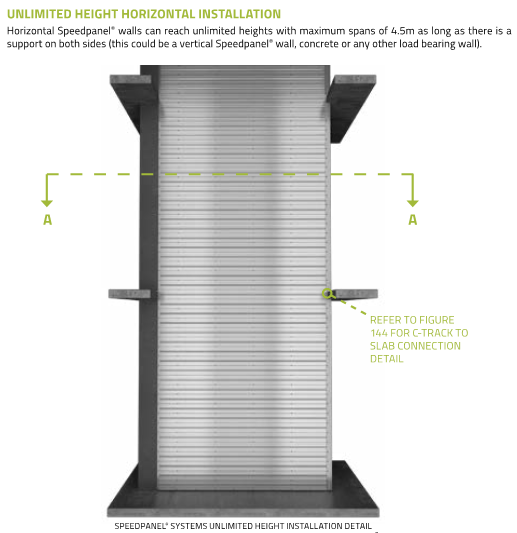

Horizontal Installation

Horizontal Speedpanel (at unlimited heights) must:

- Have a with a maximum span of 4.5m

- Supported both sides.

T-Intersections

Panel to Structure

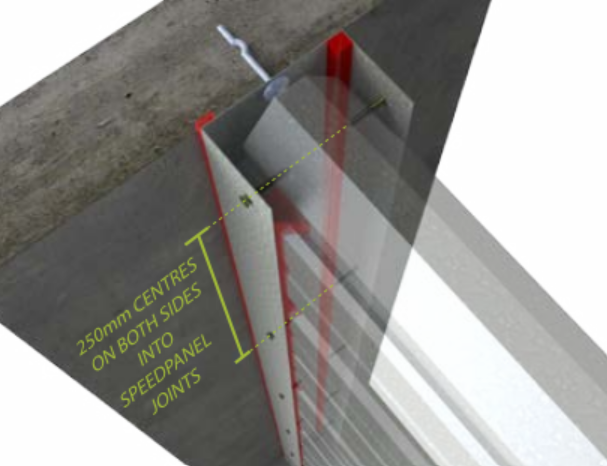

Horizontal Speedpanel (panel to structure) must have:

- 10G x 35mm SDS screws fixings on both sides of the sides of the side C-tracks at 250mm centres into every panel joint on both sides Refer Figure.

- M6.5 x 50mm mushroom head spike into structure at 500mm centres into every panel joint. (Under 5.0m in height).

- M6.5 x 50mm mushroom head spike into structure at 250mm centres into every panel joint. (Over 5.0m in height).

- Sealant applied as per Figure.

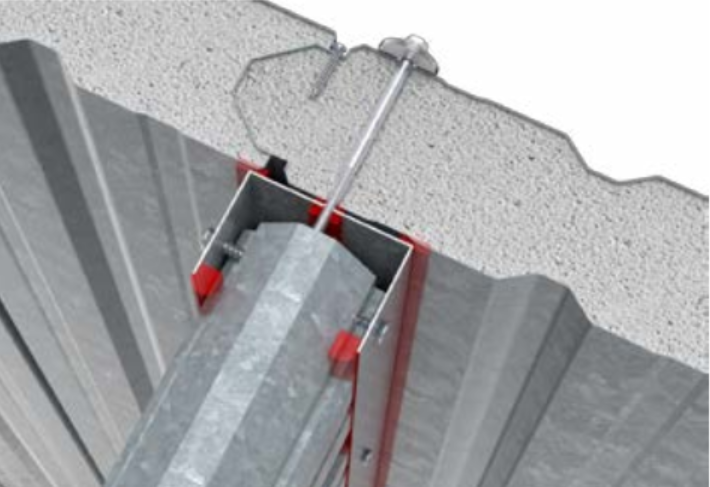

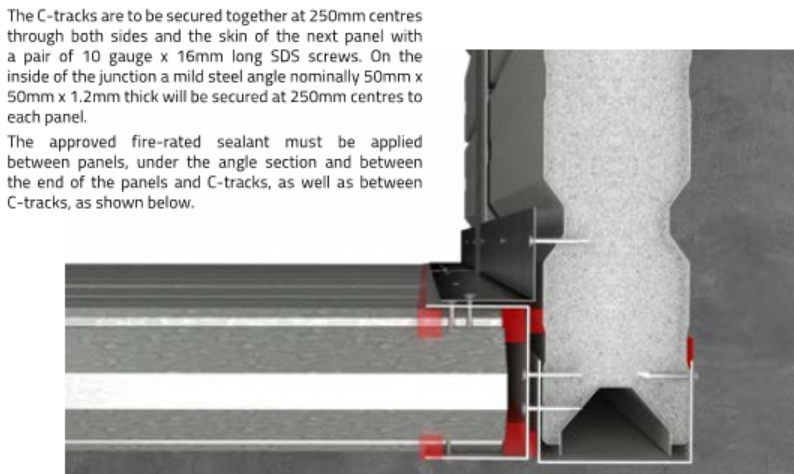

Panel to Panel (C-Track)

Horizontal Speedpanel (C-Track) must have:

- Have 35mm SDS screws at 250mm centres into every panel joint at both sides.

- Sealant applied as per Figure.

Panel to Panel (Angle)

Horizontal Speedpanel (angle) must have:

- 50 x 50 x 1.2mm angle and 35mm SDS screws at 250mm centres into every panel joint at both sides.

- Sealant applied as per Figure.

Panel to Panel (Alternative)

Horizontal Speedpanel (alternative) must have:

- SDS 14 Gauge 20tpi x 115mm and 50 x 3mm steel washer at every 250mm centres.

- Sealant applied as per Figure.

Corners

Horizontal Panel to Vertical Panel

Corner Horizontal Panel to Vertical Panel Detail must:

- Have C-tracks secured at 250mm centres with 10-gauge x 16mm long SDS screws.

- Have mild steel angle 50mm x 50mm x 1.2mm BMT secured at 250mm centres.

Pressurised Shafts

Speedpanel walls that need to be pressurised must:

- Have a bead of sealant applied around the wall perimeter on the inside and outside of the C-tracks.

- Have the sealant along each Speedpanel joint.

Penetrations

Refer to Speedpanel Walls

Document Control

June 2024 – Revised heading to ‘Speed Panel Service Shafts’