Planter Boxes

Key Considerations

- Falls

- Drainage and Overflows

- Material Selection

- Penetrations

- Preparation

- Installation and Application

Design

Planter boxes design must consider:

- Davit arms and other life safety devices not being incorporated within the planter located outside.

- Waterproofing to AS 4654

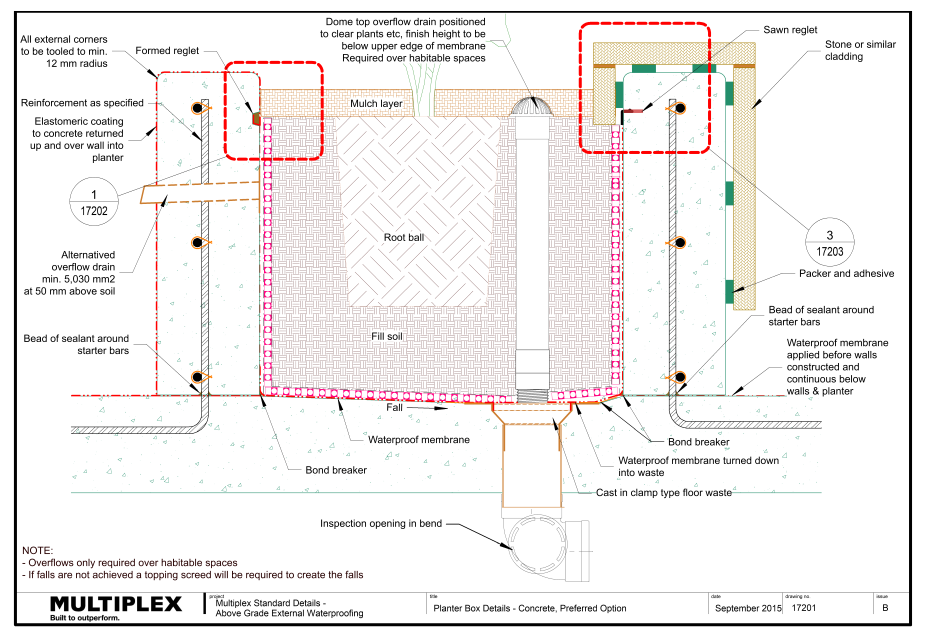

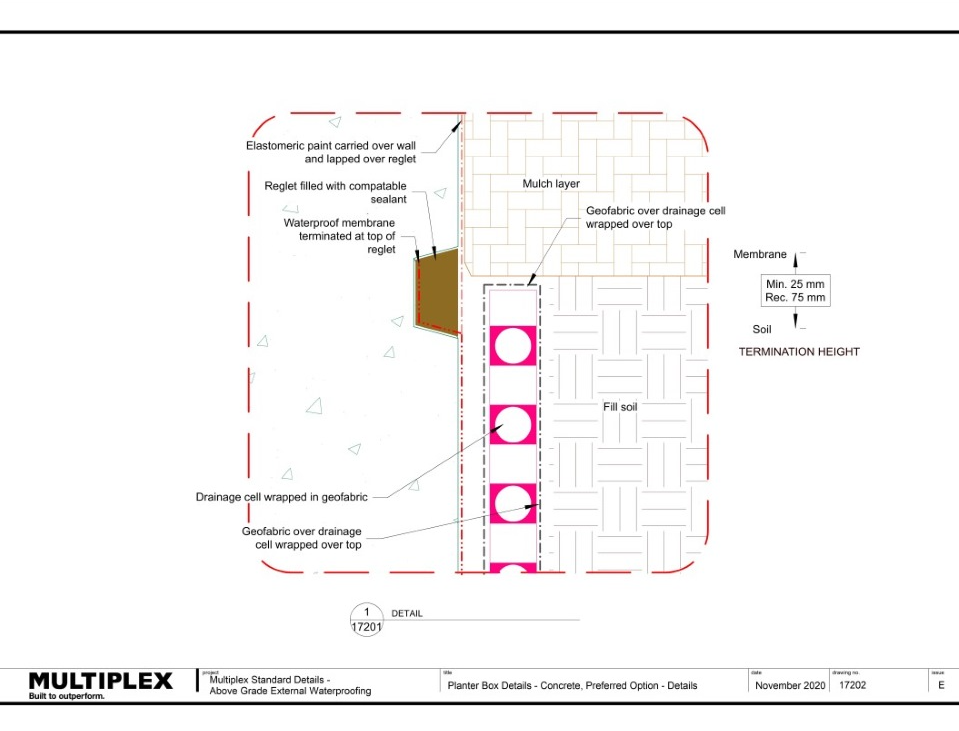

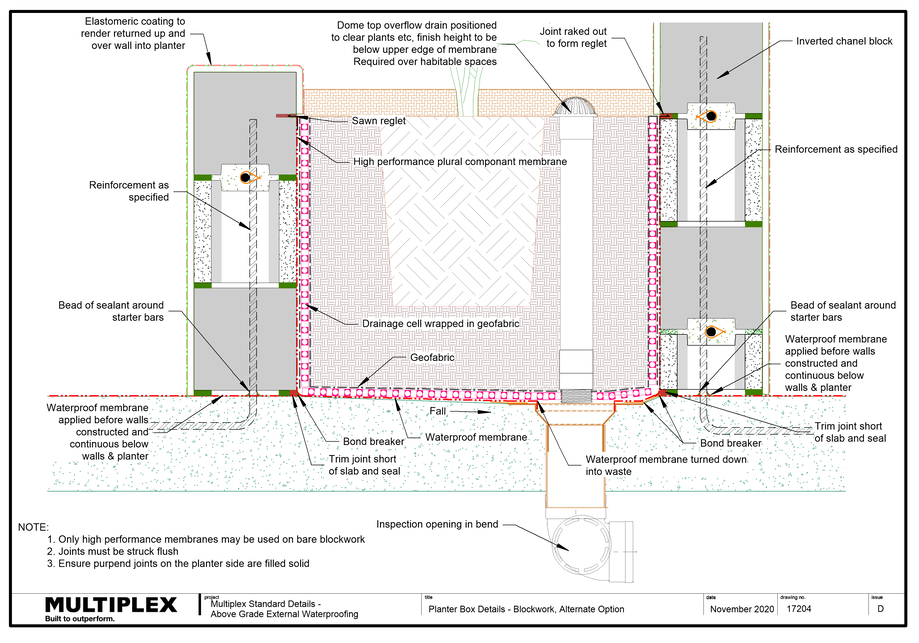

- Standard MPX 17200 series of drawings and MPX Guide to Waterproofing

- constructioned from cast in-situ reinforced concrete (Note: Concrete blockwork, reinforced and grouted, is permitted if joints are flush and a plural component membrane is used).

- Base graded to fall to a floor waste.

- Pipes or conduits being located through walls rather than the base

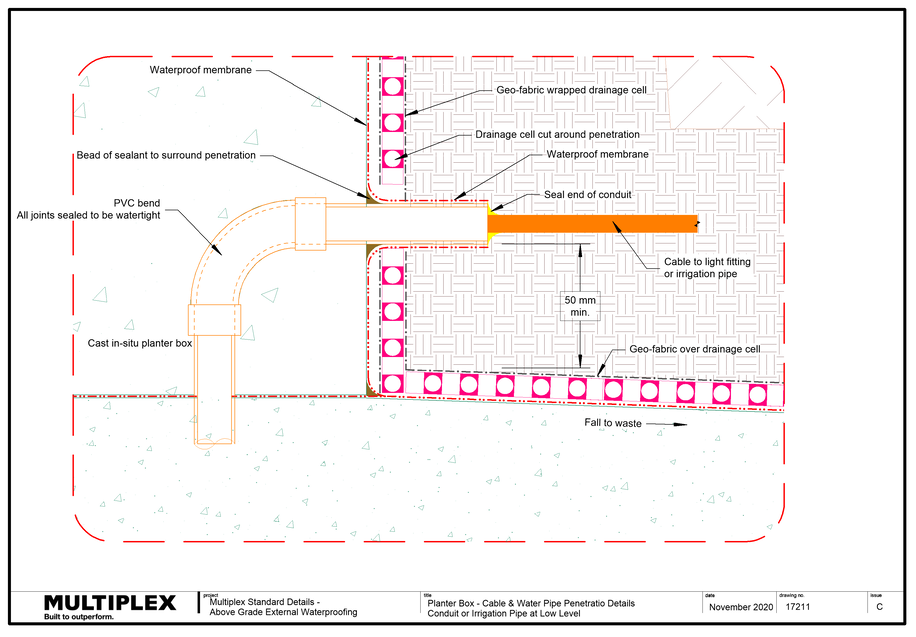

- Pipes or conduits being located not less than 50mm above the floor and spread apart.

- Stand pipes, light poles or similar being only on plinths.

Planter box membranes must:

- Be tested to AS4654.1 & AS4858.

- Be in accordance with the membrane selection chart

- Be resistant to root attack

Drainage

Planter boxes must have drainage:

- Dimensioned as per the hydraulic engineer’s details

- With a clean out or inspection opening (IO) provided below planter

- With a clean out riser up to soil level.

Overflows

Planter boxes must have overflows:

- Dimensioned as per the hydraulic engineer’s details

- 50mm above the finished soil level

- Protected from blockages caused by soil or mulch

They should also include a clean out or inspection opening (IO) provided below the planter unless the pipe can be cleared or rodded from above.

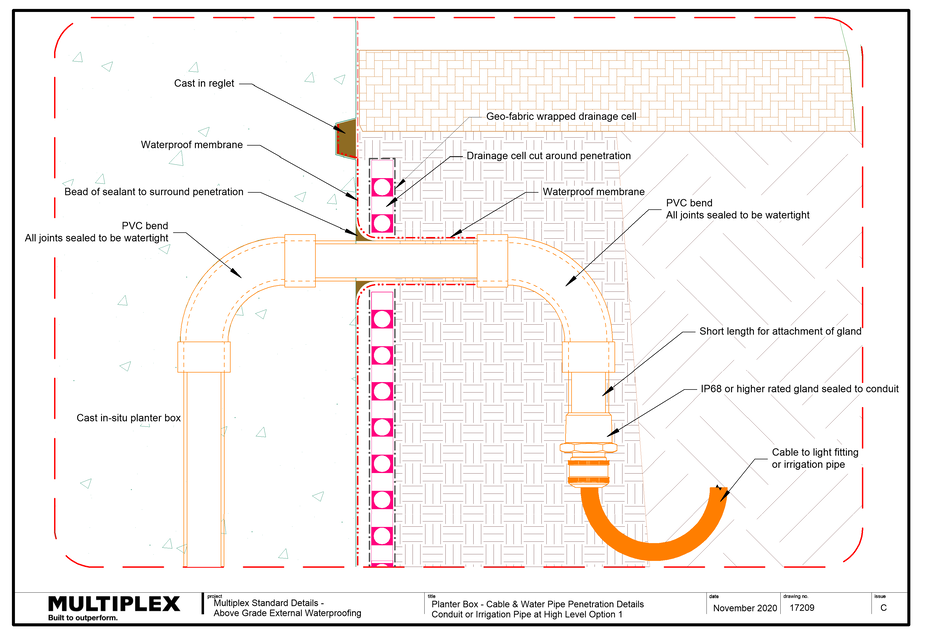

Services Penetrations

Electrical conduits and irrigation pipes must be:

- Raised above the base (not less than 50mm) with sufficient separation to allow the application of membrane in between (nominal 50mm)

- Limited in number

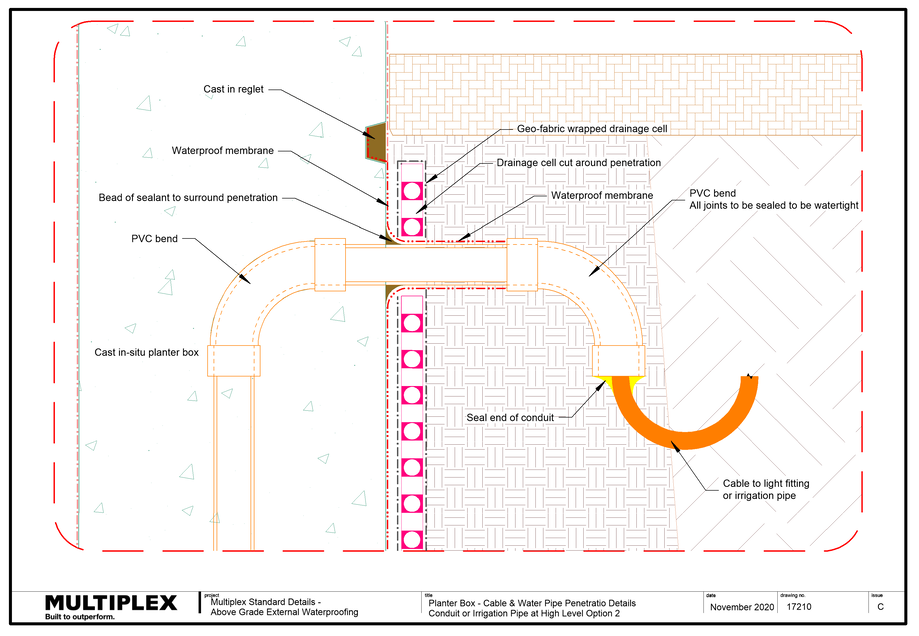

- Designed in accordance with the drawings 17209, 17210, & 17211

Preparation

Concrete Preparation

- Concrete substrates must:

- Have falls to the stormwater drainage outlet.

- Be prepared as specified by the membrane manufacturer.

- Confirm moisture content of substrate meets the requirement of the membrane manufacturer.

- Curing compound must not prevent adhesion of the selected membrane. Concrete may require additional preparation, e.g. grinding, shotblasting, etc., to remove contaminants.

- Prepare the concrete to remove:

- Form release agents

- High spots and sharp protrusions

- Loose or friable concrete

- Offsets

- Tie holes

- Blow holes greater than or equal to 2mm.

- Cracks greater than 1mm or as specified by the membrane manufacturer, must be routed out and filled flush with a sealant if specified.

Concrete Block Walls

Concrete block planter boxes must:

- Have the internal face of the joints struck flush

Bond Breakers

What are bond breakers?

A bond breaker, as stated in Australian Standard 4654 is a “system that prevents the membrane bonding to the substrate, bedding or lining”

Why is Bond Breaker required?

Bond-breakers allow movement of membranes to cater for differential movements. This will occur at the junction of different materials, and most notably, the:

- Junction of concrete floor and walls

- Vertical internal corners of walls

- Transition from concrete to plastic i.e. cast in leak control flange

- Transition from concrete to aluminium at waterstop angles

- Ends of the waterstop angles and the door frame.

The bond-breaker material increases the area over which the membrane can elongate.

The bond-breaker material must not adversely affect the performance of the membrane.

Bond breakers must be:

- Applied in accordance with manufacturer’s recommendations

- Fully cured before membrane is applied over

- Compatible with membrane.

Application

Priming

Primers must be:

- Applied as per manufacturer’s guideline

- Covered within the nominated timeframe

- Applied with the required moisture content

- Compatible with substrates, including leak control flange and other components

- Only applied when the air temperature is higher than 5 degrees or as specified by the manufacturer.

Membranes

Membranes must be:

- Terminated in accordance with the manufacturer’s guidelines

- Applied as per manufacturer’s instructions taking account of the factors that might impact the membrane performance (e.g. moisture content of the concrete, relative humidity, temperature).

- Not applied when temperature is lower than 5 degrees (refer to manufacturer’s guidelines).

- Applied with consideration to the curing time where temperatures are lower than 10 degrees or higher than 30 degrees.

- Do not apply a membrane when rain is forecast during the curing period

- Completely dry before curing can commence and flood testing or toppings are applied.

Notes:

- Failure to observe this requirement can lead to membrane re-emulsification that requires expensive remedial work.

- There is a fundamental difference between a touch dry membrane and a cured membrane.

- When preparing programs, this time frame must be allowed for.

- Weather and other environmental factors will influence the time it takes for drying and curing.

- Cold and wet = long time to dry and cure.

- Hot and dry = fast drying and curing.

- Enclosed perimeter with little to no cross ventilation = slow drying and curing.

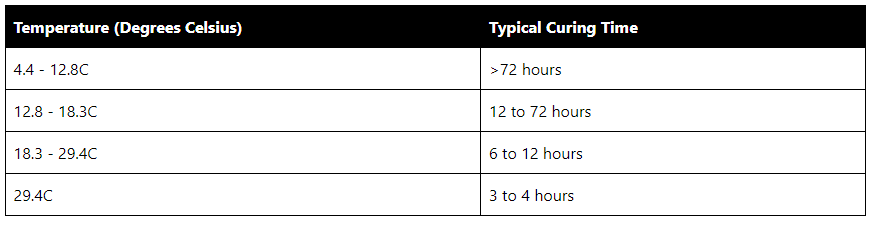

Table 1: Example temperatures and time for curing

Film Thickness

All membranes, , rely upon the final film thickness to be able to function as designed. The correct thickness ensures the mechanical properties will be preserved and the membrane will be durable and perform the desired function.

Liquid membranes must:

- Be tested with a comb during application to determine the wet film thickness as per Figure (Note: A membrane with 50% solids applied at a thickness of 2mm out of the can will dry out to 1 mm DFT).

- Be tested using an ultrasound device for cured acrylic and polyurethane membranes to determine the dry film thickness with a minimum of one test conducted and an additional test conducted for each 10m2 chosen at random.

Have records of wet and dry film thickness values recorded in the Sub-contractors Checklists.

UV Protective Coating requirement where membrane is exposed to sun light

UV Protective Coating must be:

- Applied as per manufacturer’s guideline

- Applied to membrane within the nominated timeframe

- Applied once membrane has cured and surface is dry

- Only applied when the air temperature is higher than 5 degrees or as specified by the manufacturer.

- Achieve the requirement of the UV protection underlying membrane

Protection and Drainage Cell

- Drainage cells must be installed vertical, horizontal and wrapped in geo-fabric

Services Penetrations

Electrical conduits and irrigation pipes must be:

- Installed in conduits with all joints and ends sealed.

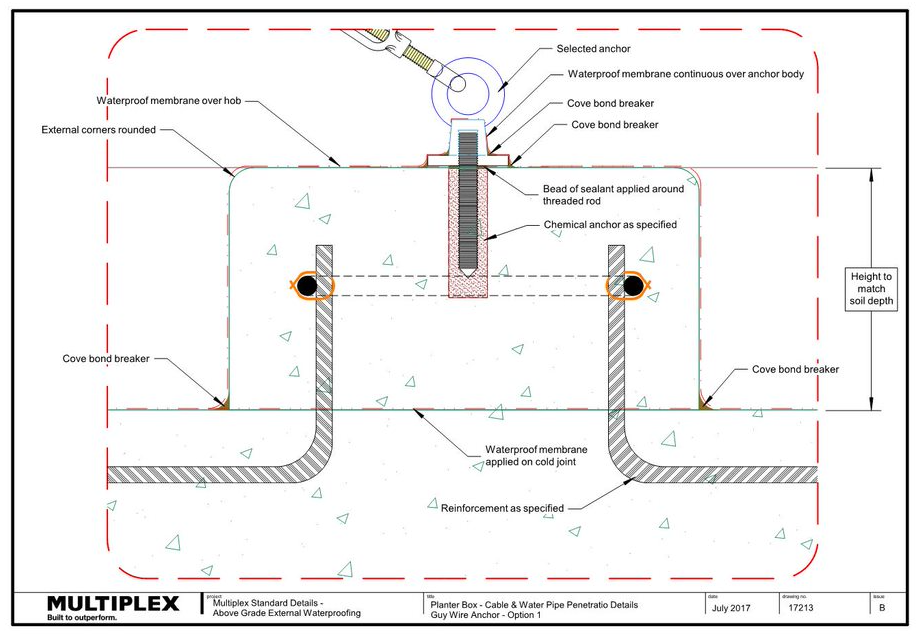

Steel posts, Columns, Light Poles, Guy Wires

Steel posts, Columns, Light Poles, Guy Wires and the like must be:

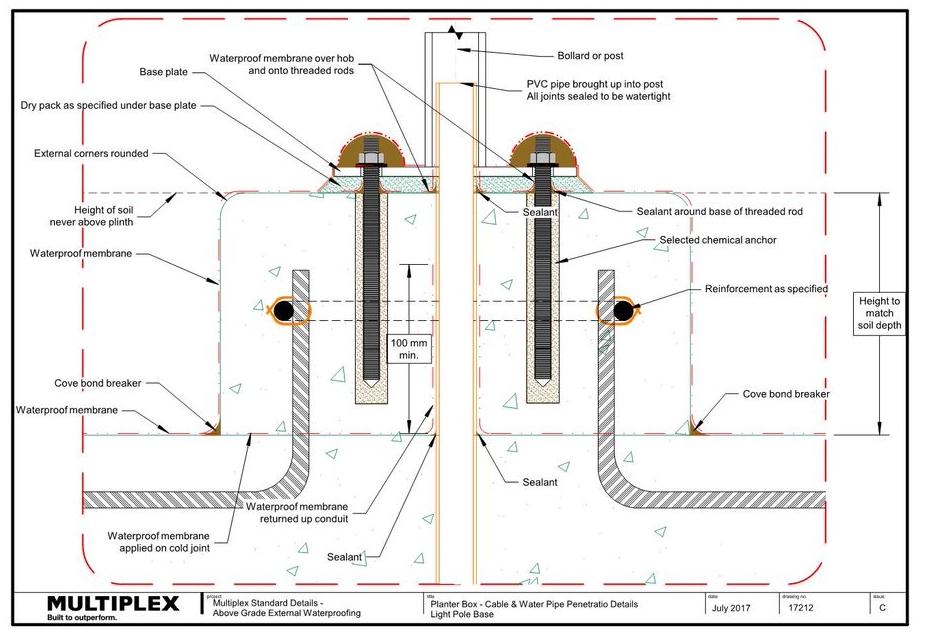

- Installed on plinths of reinforced concrete, refer to Dwg. 17213 for Guy Wire details

- Hobs raised as high as practicable, refer to Dwg. 17212 for post details

- Held down only with chemical anchors

- Waterproofed.

Multiplex Standard Details

17201 - Planter Box Details - Concrete, Preferred Option

17202 - Planter Box Details - Concrete, Preferred Option - Details

17203 - Planter Box Details - Concrete, Preferred Option - Details

17204 - Planter Box Details - Blockwork, Alternate Option

17207 - Pressure Seal Termination Details

17208 - Planter Box - Cable & Water Pipe Penetration Details, Conduit or Irrigation Pipe

17209 - Planter Box - Cable & Water Pipe Penetration Details, Conduit or Irrigation Pipe at High Level Option 1

17210 - Planter Box - Cable & Water Pipe Penetration Details, Conduit or Irrigation Pipe at High Level Option 2

17211 - Planter Box - Cable & Water Pipe Penetration Details, Conduit or Irrigation Pipe at Low Level

17212 - Planter Box - Cable & Water Pipe Penetration Details, Light Pole Base

17213 - Planter Box - Cable & Water Pipe Penetration Details, Guy Wire Anchor - Option 1

17214 - Planter Box - Cable & Water Pipe Penetration Details, Guy Wire Anchor - Option 2

Document Control

Version 03 November 2020