Natural Stone

Key Considerations

- Joint locations

- Efflorescence control

- Material selection

- Durability

- Stain resistance.

- Strength.

- Resistance to abrasion.

Design and Planning

- In all instances, except for very minor low risk use of stone, a suitable consultant (refer recommendations in table below) must be engaged by each project.

- Generally, the scope shall include the following:

- Review plans and specifications for the proposed stone types and uses.

- Comment on the suitability of what is specified.

- Offer alternatives if specified stone is unsuitable.

- Provide a technical specification for the project.

- Review and comment on sample submissions from Subcontractors/Suppliers.

- Review and comment on any historical tests or data provided by the Subcontractors/Suppliers.

- Review and comment on Subcontractor submissions, workshop drawings, etc.

- Recommend what stone tests are required and at what frequency.

- Testing of stone samples.

- Actively participate in meetings and workshops as required by MPX.

- Inspect the work during construction. Report to MPX what non-conformances or other matters for concern are observed.

- Carry out a final inspection at complete to confirm that the work is in accordance with the technical specification.

- Assist in compilation of Operation & Maintenance Manual.

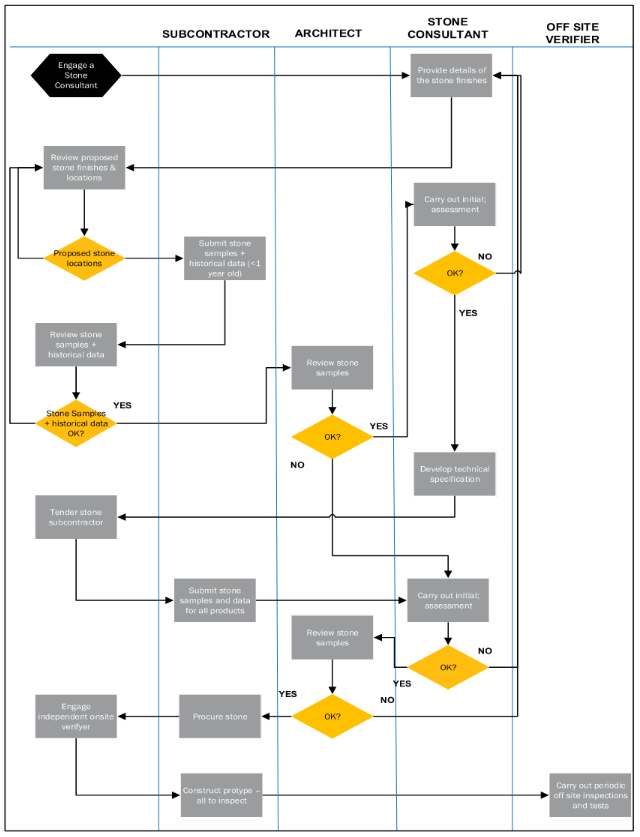

The stone design and selection process must be in accordance with the flowchart below:

- Inform the client in writing that although all due care and diligence has been used to select the stone, provide appropriate design and correctly install the stone, due to the uncontrolled nature of its constituents, the long term performance of the stone cannot be fully understood.

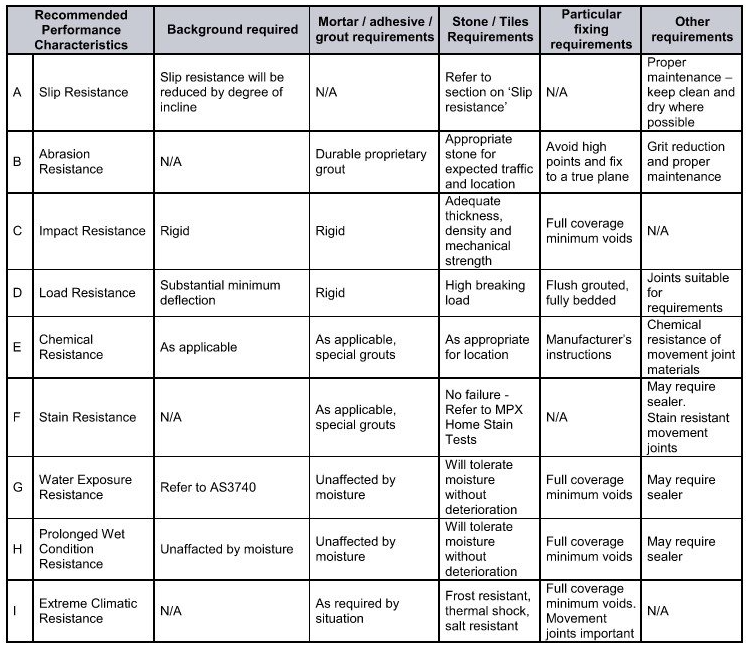

- Guidance on the performance characteristics of stone in various locations is given in Table 1

Table 1 - Minimum Recommended Performance Characteristics.

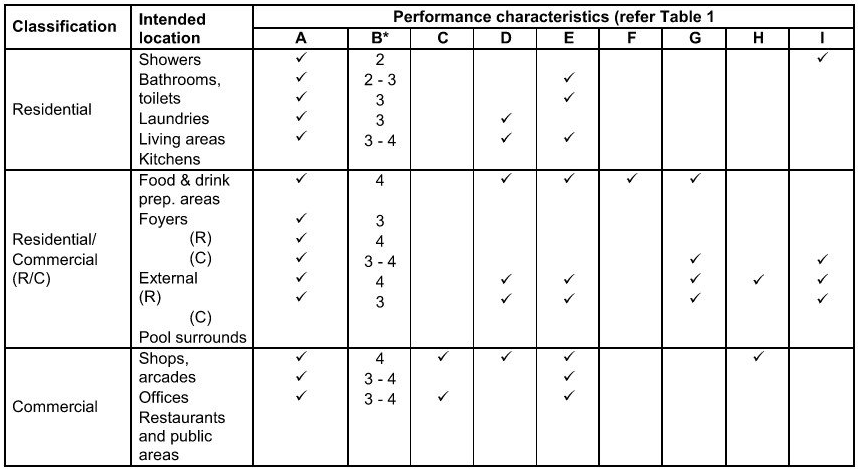

The information in Tables 1 & 2 has been obtained from and is based upon Australian Standard 3958: 1992, “Ceramic tiles, Part 2: Guide to the selection of a ceramic tiling system”.

Table 2 - Minimum Recommended Performance Characteristics by Classification.

NOTE: In order to ensure that these performance characteristics can be maintained it is essential that the systems used are compatible with the anticipated intrinsic movements of the stone & tiles, its substrate and the base structure.

Testing

- All stone proposed to be used must be tested. Testing details are to be specified by the Stone Consultant or as specified in the specification for low risk use.

- Stone will typically be tested against the following standards:

- Water Absorption - ASTM C97M-09

- Bulk Specific Gravity - ASTM C97M-09

- Compressive Strength – ASTM C170M-09

- Flexural Strength - ASTM C880M-09

- Modulus of Rupture - ASTM C99M-09

- Resistance to Salt Attack - AS/NZS 4456.10-2003

- Resistance to Acid Attack - Surface sensitivity, immersion.

- Determination of Frost Resistance (Freeze/Thaw) - ISO 10545-12:1995

- Abrasion Resistance - ASTM C1353-09

- Dimensional Stability

- Coefficient of Thermal Expansion

- Home Staining (refer below)

- Test reports received for initial appraisal must be less than 12 months old.

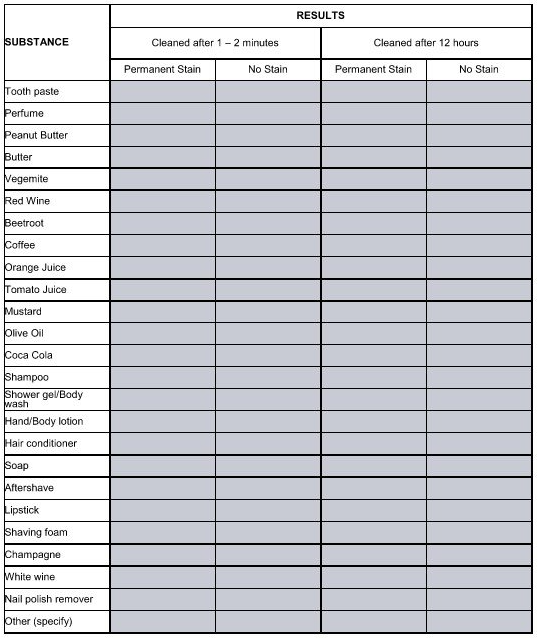

- MPX Home Staining test must be undertaken in accordance with process below:

- Obtain samples of material as proposed for use, i.e. same finish, sealer etc.

- Apply two separate patches of the domestic substances listed below to the samples. Patches to be approx. 30 mm diameter. Mark tile with permanent marker to indicate each substance and its location.

- After 1-2 minutes attempt to remove one patch of each substance using only a sponge and warm water. Record on the table below whether or not a stain remains on the stone. Take care not to contaminate adjacent samples.

- After 12 hours attempt to remove the remaining patch of each substance using only a sponge and warm water.

- Record on the table below whether or not a stain remains on the stone.

Beds and Screeds

Refer to section ‘Screeds and Acoustic Underlays’

Secondary Membranes

Secondary waterproof membranes must be used to control efflorescence whenever either natural or reconstituted stone is used irrespective of location if exposed to water, e.g. bathrooms, etc.

Control Joints

Refer to section ‘Control Joints’

Document Control

Version 01, December 2020 - New section detailing the requirements for stone that were detailed in the old Multiplex Guide.