Clay Masonry (Brick Veneer)

Key Considerations

- Penetration details

- Location of control joints

- Flashings and damp proof courses

What are brick walls?

Brick walls are walls constructed from small units of masonry known as bricks. Bricks are stacked on top of each other in a pattern and bound together with mortar.

Each row of bricks is called a course. The horizontal joint between bricks is called a bed joint.

The vertical joint between the bricks is called a perpend joint; often shortened to “perp” or “perps”.

Generally Multiplex uses 2 types, both made of clay:

- Dry pressed bricks: most easily recognised by the depression in one face which is called a “frog”

- Extruded bricks: which can be recognised by the series of holes (which can be round or square) made through the height of the brick.

Selection

Samples and prototypes in addition to those outlined in the specification must be submitted/built as per link below.

Face Brick Colour Variations

Why is blending important?

- To counteract the colour variations that occur when bricks are manufactured in batches.

- To eliminate banding by distributing units with colour variations somewhat evenly throughout the wall, thus ensuring a satisfactory appearance in the finished masonry.

Blending Bricks

- It is critical to understand the colour variations possible.

- Before laying open 3 to 6 packs

- Select units from down and across packs

- Mixing packs and colours will produce an even distribution.

Mortar Joints

What are mortar joints?

Mortar is the jointing between the bricks made of sand and cement.

Why are mortar joints required?

Four principal functions of mortar are to:

- Provide an even bedding for the blocks and allow course levels by taking up small variations in unit dimensions.

- Transmit compressive and tensile loads.

- Hold the bricks together in the wall by bonding to them, so that tensile and shear forces can be carried. (This is often referred to as bond strength). This is particularly important so that units on top of a wall are not easily dislodged.

- Assist with weatherproofing.

Mortar joints must be maximum 10mm thick for both bed and perpend joints.

Perpend joints must be filled full.

Mortar mixes must:

- Be batched accurately using volume batching methods.

- Have clean sand

- Have clean water

- Be discarded and not re-tempered after the initial set of the cement has taken place.

Cavities

What are cavities?

A cavity creates an air gap between the outer course and the inner course or framing.

Why are cavities required?

Cavities prevent water penetration from the exposed face through to the inner, unexposed face of the wall.

Cavities must be:

- A minimum of 25mm from sarking or insulation.

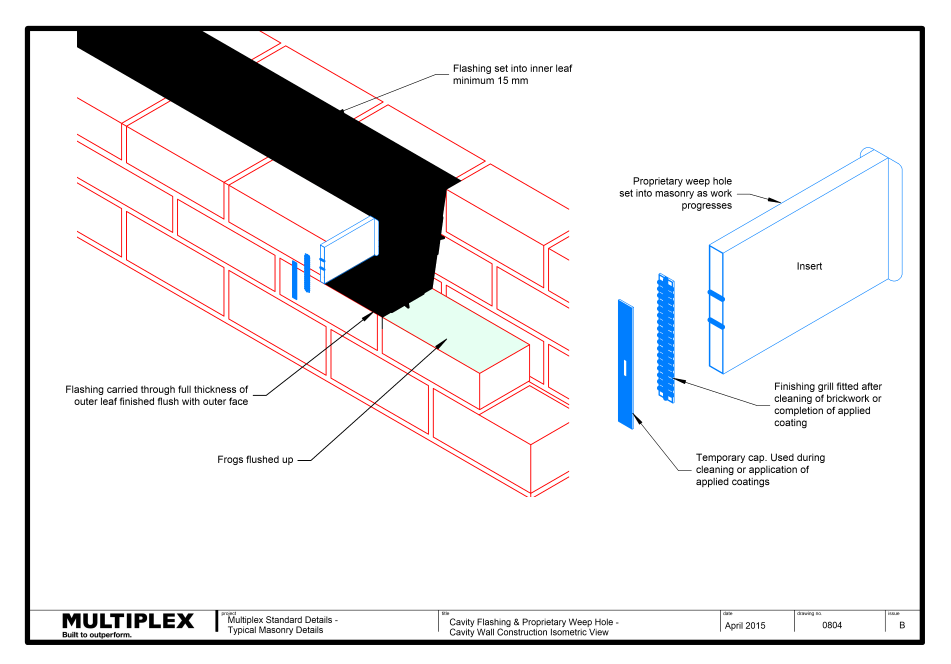

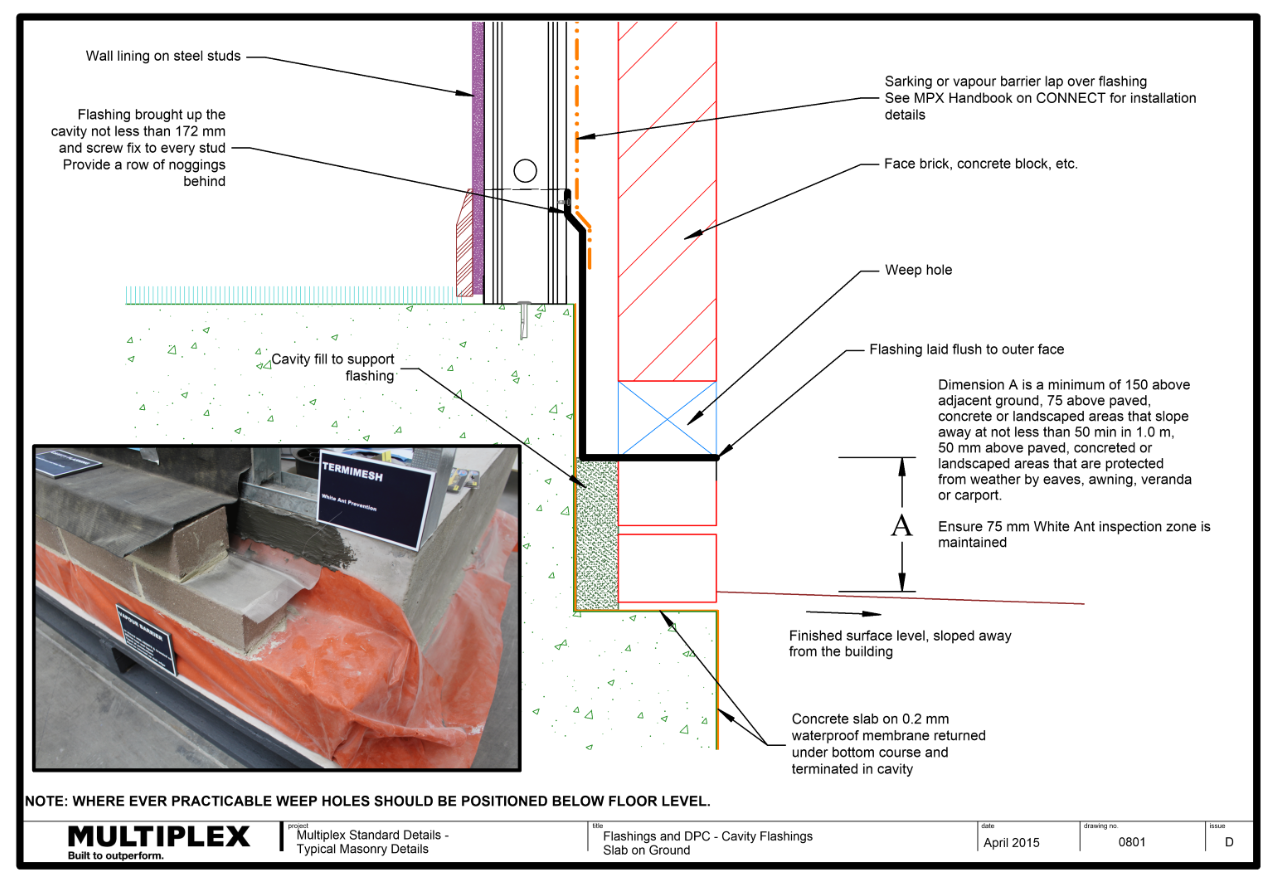

- Drained by weep holes provided no further apart than 1200mm and directly on the cavity flashing.

- Clean of mortar droppings.

Weepholes

What are weepholes?

Weepholes are simply drain holes through an external wall.

Why are weepholes required?

Weepholes are provided to drain moisture from the cavity.

Proprietary weep hole formers must be:

- Provided in the masonry course immediately above the flashing, at centres not exceeding 1200mm.

- Built into the external leaf of cavity walls or veneer walls at centres not exceeding 1200mm in the course immediately above a DPC or flashing.

- Above and below the opening in the centre when openings are less than 900 mm wide.

Ties

What are wall ties?

A wall tie is a component used to attach the external brick wall to the inner structural support.

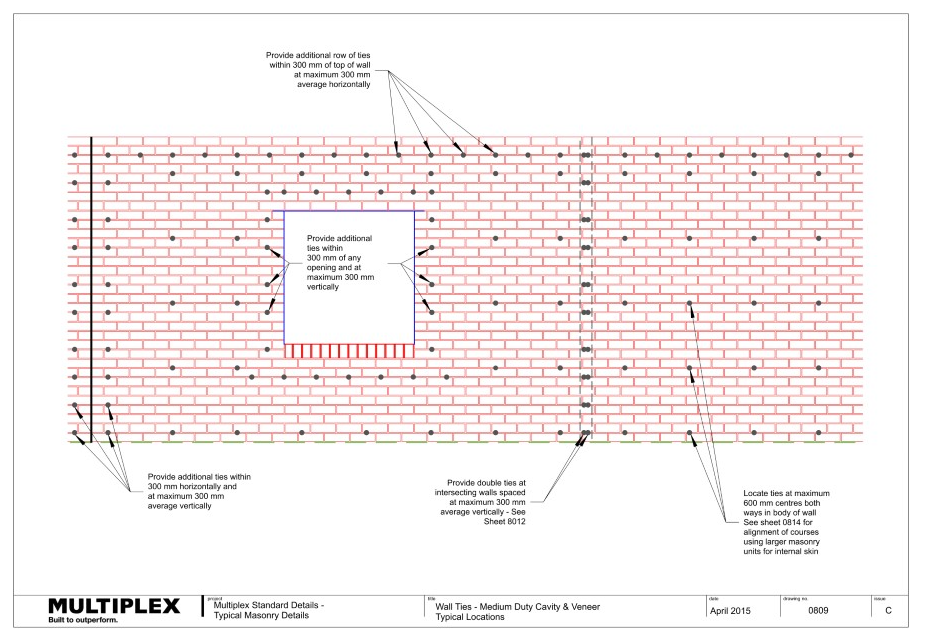

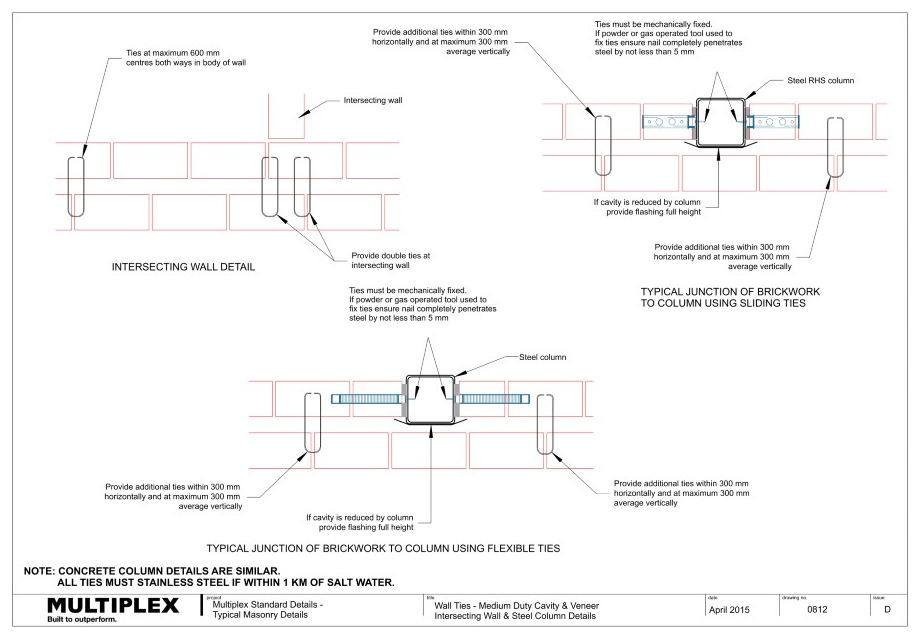

Wall ties must:

- Have minimum embedment of 50mm into the bed joint, never in the perpend

- Have minimum cover of 15mm from an exposed face

- Be installed with the correct orientation

- Have no contamination by mortar droppings in the cavity

- Be provided at no greater than 600mm centres both ways in the body of the wall

- Be provided at no greater than 300mm centres vertically at the following locations:

- Door or window openings

- Either side of control joints

- Within 300mm above and below each intermediate floor

- Each side of concrete or steel columns

- At Intersecting walls.

Flashings & Damp Proof Courses

What are a cavity flashings and damp proof courses (DPC)?

A DPC is:

- Provided to prevent moisture from moving upward or downward through the masonry.

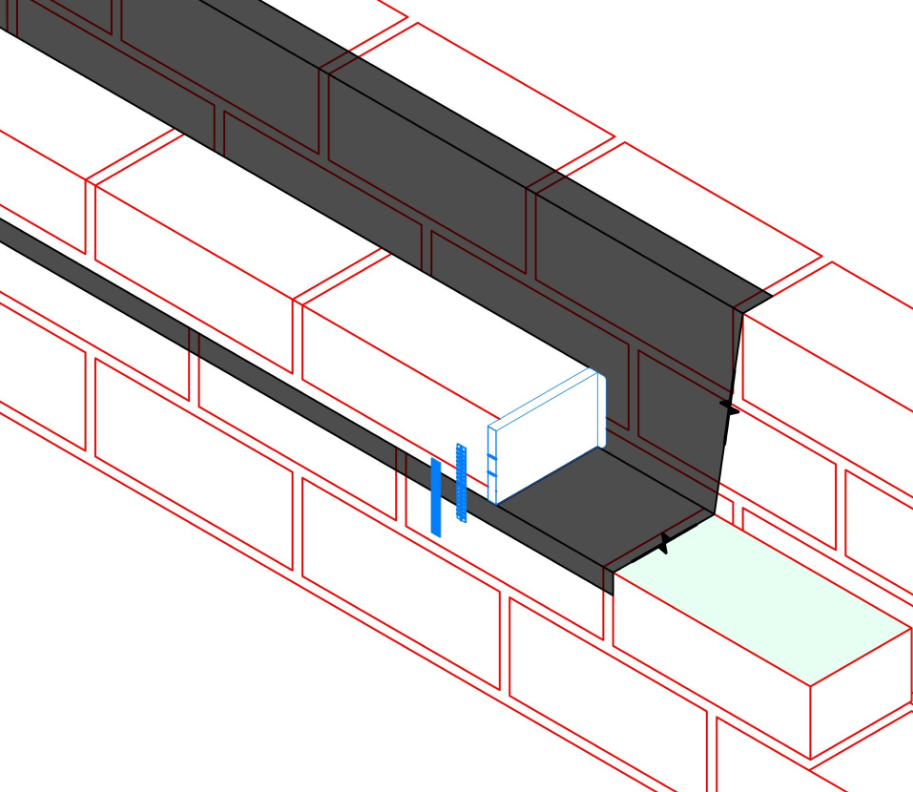

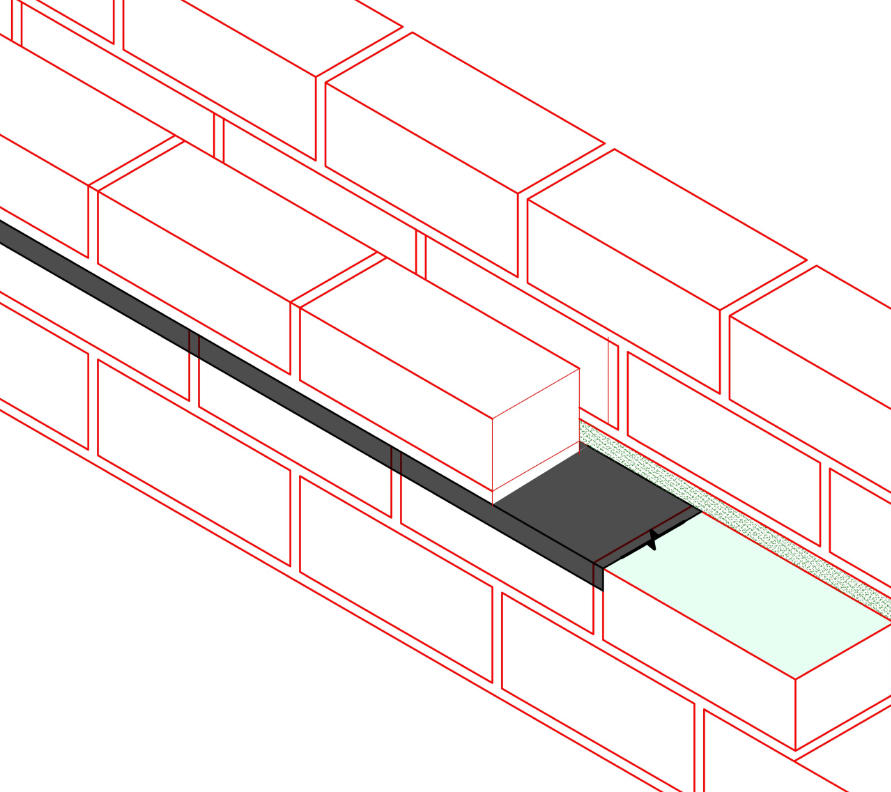

Cavity flashings are required:

- To prevent moisture from moving upward or downward through the masonry.

- To prevent moisture passing from exterior to the interior of a building, including passing across a cavity.

- To shed moisture from a cavity to the outer face of a masonry wall.

Note: A cavity flashing can be a damp proof course, but a damp proof course cannot be a cavity flashing.

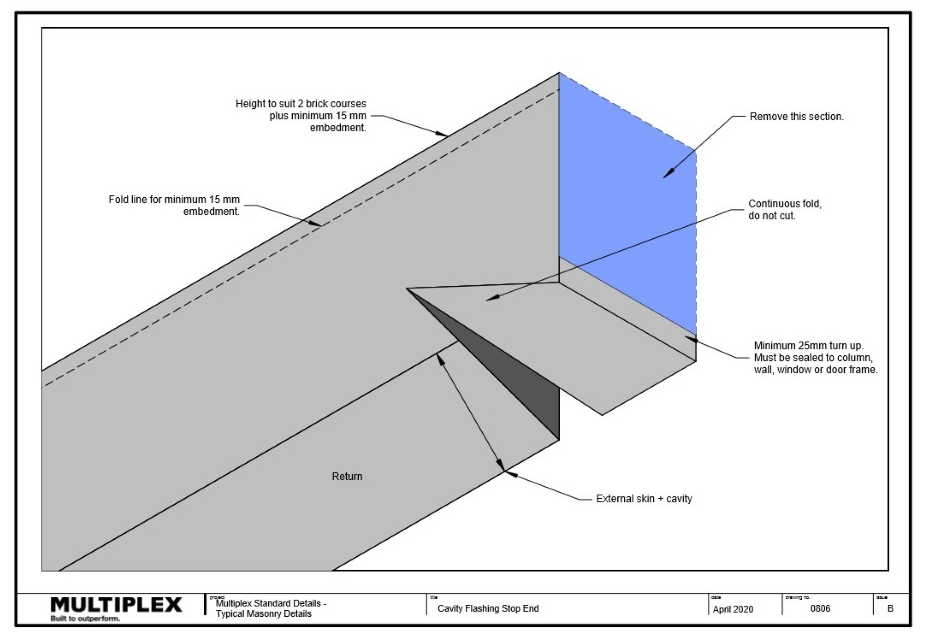

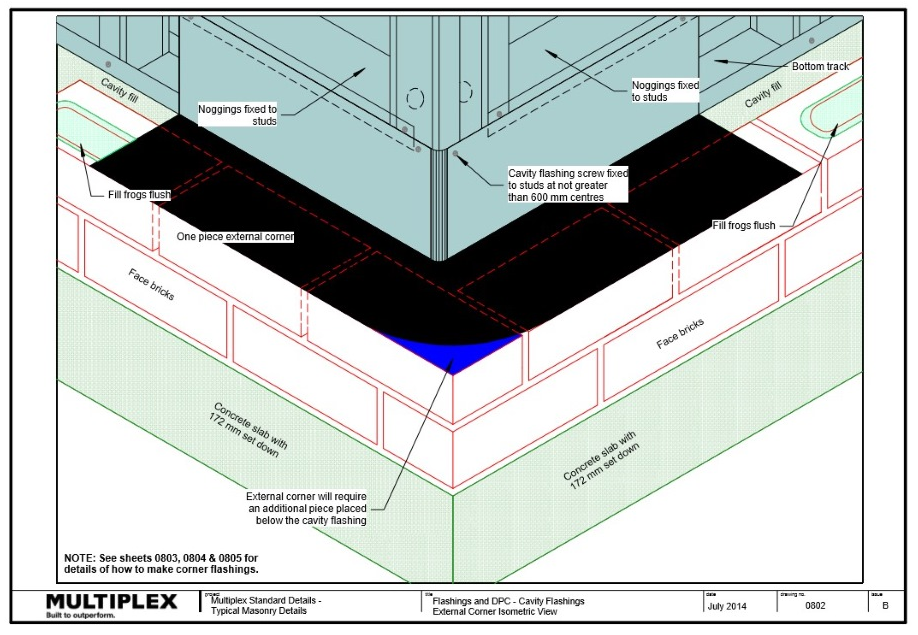

Cavity flashings and DPCs must be:

- Passed through the entire width of the masonry leaf

- Lapped to a minimum 200mm and sealed with an approved sealant

- Returned up the cavity a minimum of 172mm or as specified (flashing only)

- Stepped at changes of floor or ground level.

- At least 75mm above-finished surface level of adjacent paved, concreted or landscaped areas that must slope away from the wall.

- At least 50mm above finished paved or concreted areas sloping at least 50mm over the first 1m from the building and protected from the direct effects of the weather by a carport, veranda or similar.

- At least 150mm above the adjacent finished ground in all other cases.

- Screwed to steel studs at not greater than 600mm centres (flashing only).

- Positioned above and below openings where they are to extend 100 mm past the end of the opening (flashing only).

In addition cavity flashings and DPCs must:

- Have corners formed, both internal and external

- Not be breached or punctured.

Sarking

What is Sarking?

Sarking, underlay or wall wrap is a pliable sheet material installed into wall cavities and fastened to the studs, to provide water, thermal, vapour and air control.

Sarking can be breathable or non-breathable. The type suitable for a project will depend upon the location.

Sarkings must:

- Be fixed as specified by the manufacturer:

- For steel or aluminum framing, at 300mm centres using 8g galvanized self-drilling screws and 25mm washers.

- For timber framing, using metallic-coated clouts, or punched multi-point metallic coated steel brads.

- Be correctly orientated, i.e. horizontal, and not vertical and dull side out

- Be installed from the bottom up so that the upper sheet overlaps the lower by 150mm

- Have vertical end laps positioned on studs, lapped 100mm and staggered one full stud spacing between runs

- Have the bottom terminated to the cavity flashing so that condensation drains to the outside of the building

- Be continuous around corners with the vertical joint located away from the corner

- Have all joints taped to be air-tight

- Trimmed and made airtight at all window and door openings

- Be branded with the manufacturer and Australian Standard 4200.1 details.

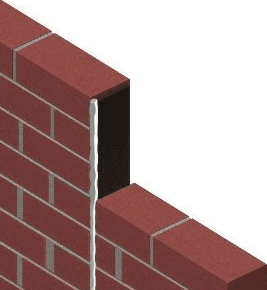

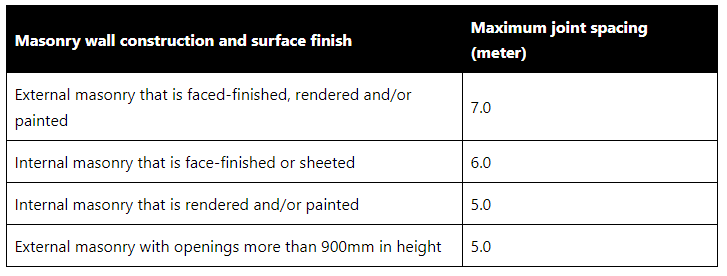

Control Joints

What are control joints?

Control joints are discontinuities in the length and height of a wall.

Joints are normally bridged by metal ties or dowels to ensure the two sides of the joint maintain alignment.

Why are control joints required?

Control joints are required in clay masonry to allow for the expansion of clay, and they are referred to as expansion joints.

Joints must be:

- Located strictly as detailed in both the Architectural and Structural drawings.

- Cleaned and include a compressible filler (e.g. “Abelflex”)

- Located:

- Where the height of a wall changes by more than 20% of its lesser height.

- Where walls change thickness.

- At control or construction joints in the structure.

- At a distance from all corners not greater than 4500mm and as close to the corner as practical.

- At junctions of walls that are constructed of different masonry or other materials

- In accordance with AS3700 Table 4.2 outlined below:

Lintels and Shelf Angles

What are lintels and shelf angles?

A lintel is a structural member that supports masonry over an opening.

A shelf angle is a member attached to the edge of a slab or other horizontal structural element to support a masonry wall.

Lintels must:

- Have end bearing on each side of an opening of not less than 100mm in length for openings up to 1000mm wide and 150mm for wider openings.

- Be hot dipped galvanised unless closer to saltwater than 1km, then they must be stainless steel.

- Be supported during installation to prevent bowing.

- Be wrapped in chicken wire if rendered.

Note: Steel lintels cannot be used in a wall requiring a fire resistance level.

Document Control

Version 2.1, April 2021