Flexible Duct

Supports

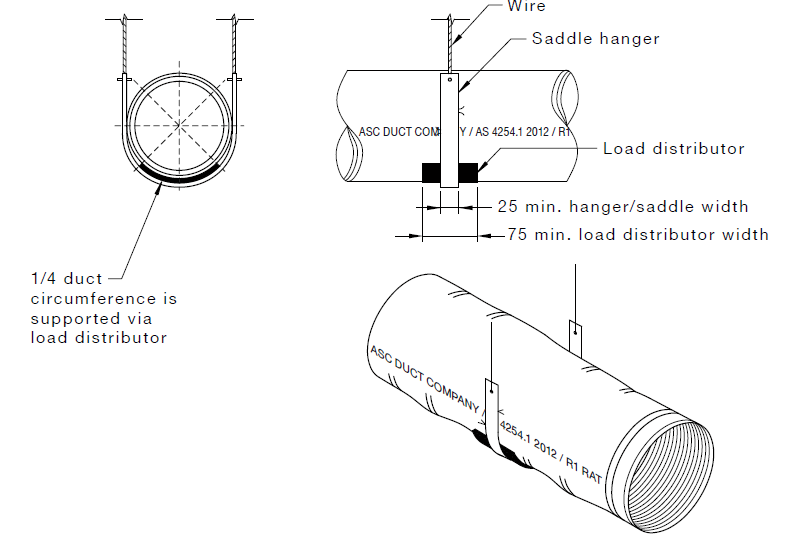

- Flexible duct hangers or saddles in contact with the flexible duct in accordance with Clause 2.5.3 of AS4254.1 must:

- Be a minimum width of 25mm.

- Have semi-rigid, fire resistant, load distributing support material with a minimum width of 75mm for at least a quarter of its circumference.

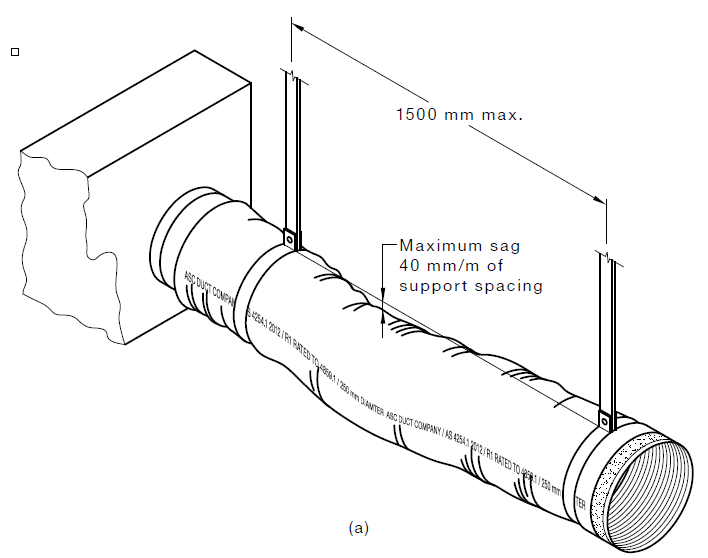

Flexible duct support must be spaced in accordance with Clause 2.5.3 of AS4254.1:

- No greater than 1500mm apart

- With no greater than 40mm/m of sag per support.

Connections

- Flexible duct must be:

- Cut to length when less than a full length is required, N.B. excess removed.

- A single length of 6 m maximum. No intermediate joins are permitted. (Classes 4 to 9)

- Not more than two lengths of up to 6m (Classes 1 to 3)

- Attached to spigots preferably of min 150 mm in length.

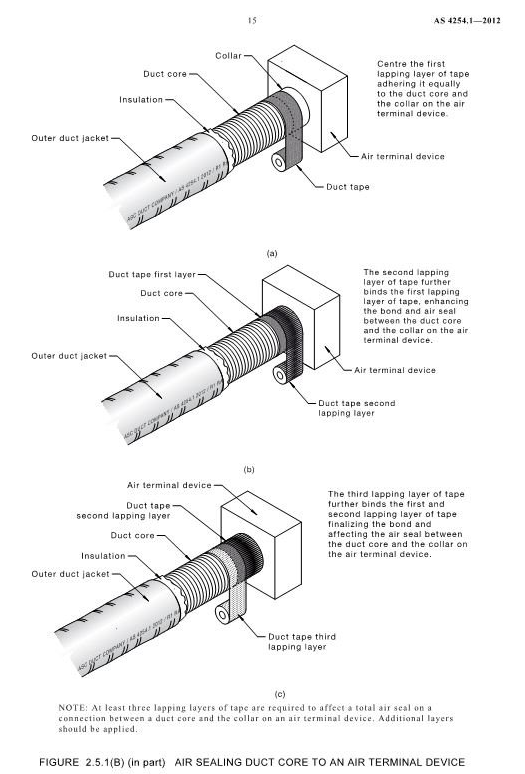

- Where duct tape is used as a sealing media, it must be:

- Minimum 0.15 mm thick and 48 mm wide

- Minimum of three overlapping wraps adhered to a collar on an air terminal device as outlined below.

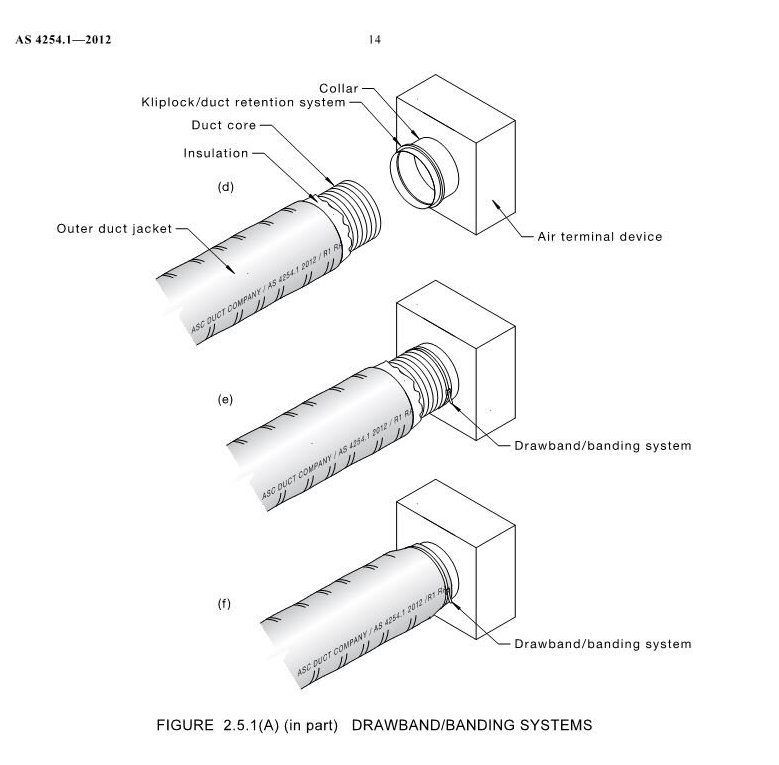

- Where mechanical fixing is used, it must be fastened permanently to circular collars on air terminal devices by means of a drawband/banding system located over the top of the air seal.

- Vapour seals (where required) are to be continuous and any tears patched/taped up

Click on the image for an enlarged view

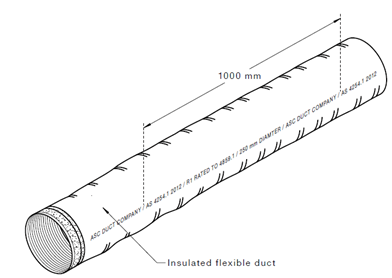

Labelling

- Labels on the outer jacket/sleeve of all insulated flexible ductwork in accordance with Clause 2.7 of AS4254.1 must:

- Be repeated along the total length of the ductwork at 1000 mm intervals

- Include the following information:

- Name of manufacturer

- Compliance with AS 4254.1

- The R value of the flexible duct.

Changes in Direction

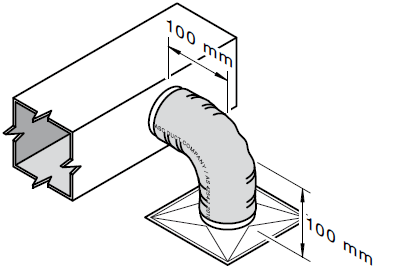

- Flexible duct work must extend straight for 100 mm from the connection to an air terminal device prior to any change of direction.

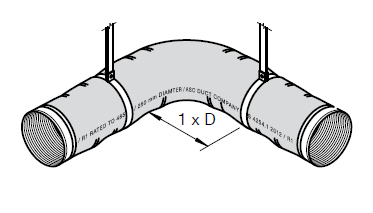

- Flexible duct work must be installed with a minimum bend radius to flexible duct diameter of 1 to 1.

- Nude core (uninsulated) duct is only be used for exhaust systems such as toilet, general and miscellaneous exhausts, never for bathrooms, laundries or similar steam generating areas.