Shotcrete

Key Considerations

- Surface Preparation

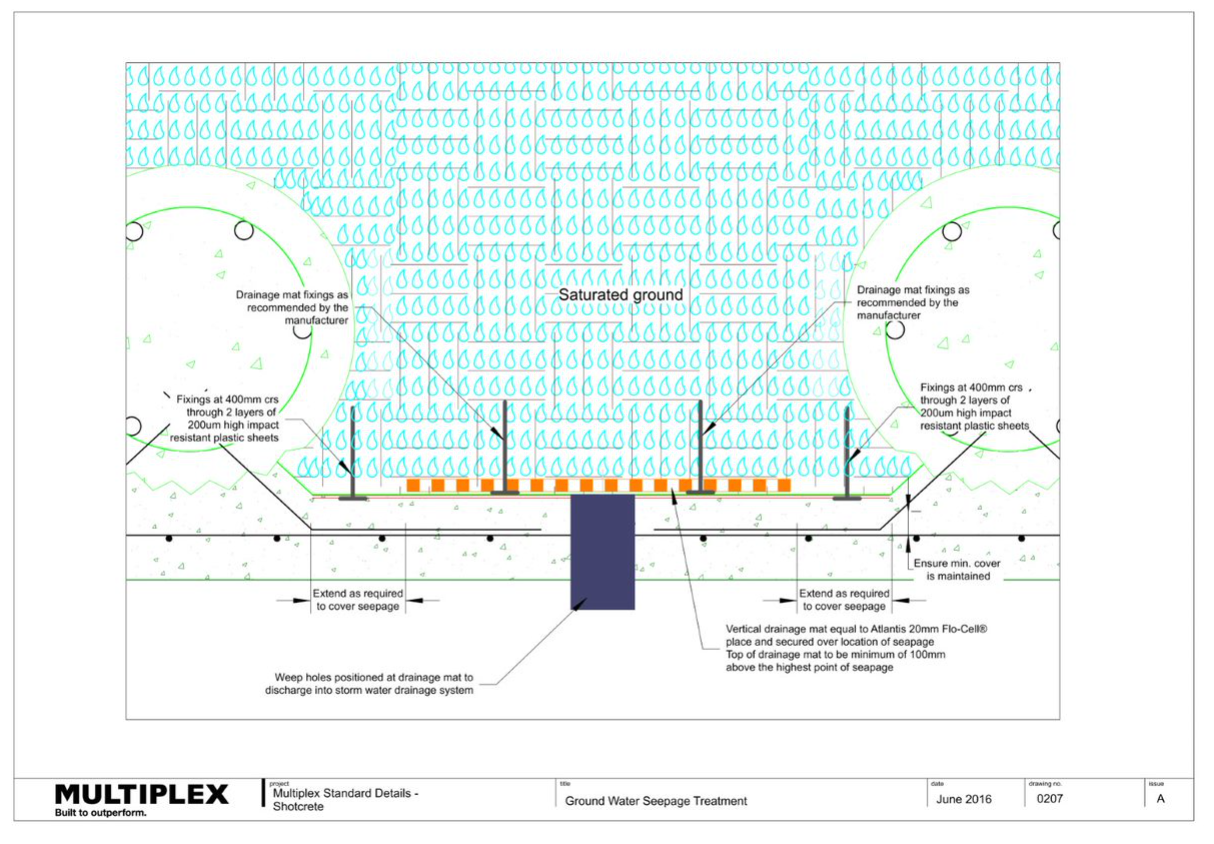

- Drainage

- Cover

- Shotcrete thickness

- Qualification of applicators

What is shotcrete?

Shotcrete is a mixture of aggregate and portland cement, conveyed by compressed air to the nozzle of a spray gun, where water is added. The wet mixture is then sprayed in place. For structural uses, shotcrete is usually applied over a framework of reinforcing bars and steel mesh.

Preparation

- Prepare all surfaces to be shotcreted prior to application of shotcrete.

Earth Surfaces

- Prior to shotcreting:

- Compact and trim the earth surface to line and grade to enable the designed shotcrete thickness to be achieved.

- Remove all loose soil or other material from the trimmed surface.

- Prevent excessive absorption of mixing water from the shotcrete by:

- Pre-wetting all earth surfaces to be shotcreted (but keeping the surface drained of free water)

- Installing a moisture barrier system to stop the movement of moisture from the newly placed shotcrete into the earth. When sheet materials are used, prevent wrinkling or folding to stop voids being formed behind the moisture barrier. Take extra care in the sequence of application or apply a flash coat to prevent shotcrete slippage.

Rock Surfaces

- Clear all rock surfaces to be shotcreted of loose material, debris, chips, mud, dirt, or other foreign matter prior to shotcreting.

- After the loose material has been removed, wash the surface as required with a high-pressure air/water jet or by other means.

- After the above preparation is carried out, pre-wet the rock surface prior to the application of shotcrete.

- Remove any excess free water by blowing with oil-free dry compressed air.

Concrete Surfaces

- Clear existing concrete surfaces to be shotcreted of any spalled, cracked, deteriorated, loose, unsound and/or chemically contaminated concrete until a sound and uncontaminated concrete is reached.

- Where shotcrete is to be placed against a smooth concrete surface, roughen the surface by mechanical methods.

- After the above preparation is carried out, pre-wet the concrete surface prior to the application of shotcrete.

- Remove any excess free water by blowing with oil-free dry compressed air.

Post-installed Reinforcing Bars

- Ensure post-installed reinforcing bars are installed in accordance with manufacturer's instructions, inspected and holes cleaned.

Test Panel

- Prior to commencing construction, construct test panels. The test panels must be at least 750mm x 750mm or constructed to the same thickness as the works, whichever is the greater.

- Carry out sampling and testing in accordance with the specification.

Application

- Apply shotcrete in layers not exceeding 150mm in thickness and with adequate adhesion to the surface or previous layers of shotcrete to prevent sloughing, sagging or slumping.

- Before shotcreting is resumed, prepare (scabble) the hardened concrete surface.

- Remove shotcrete that is segregated, loose, porous or otherwise uncompacted prior to the application of new layer of shotcrete over it.

- Cure the completed work or portion immediately following finishing.

- Monitor thickness using depth gauges during application of shotcrete to enable monitoring of shotcrete thickness.

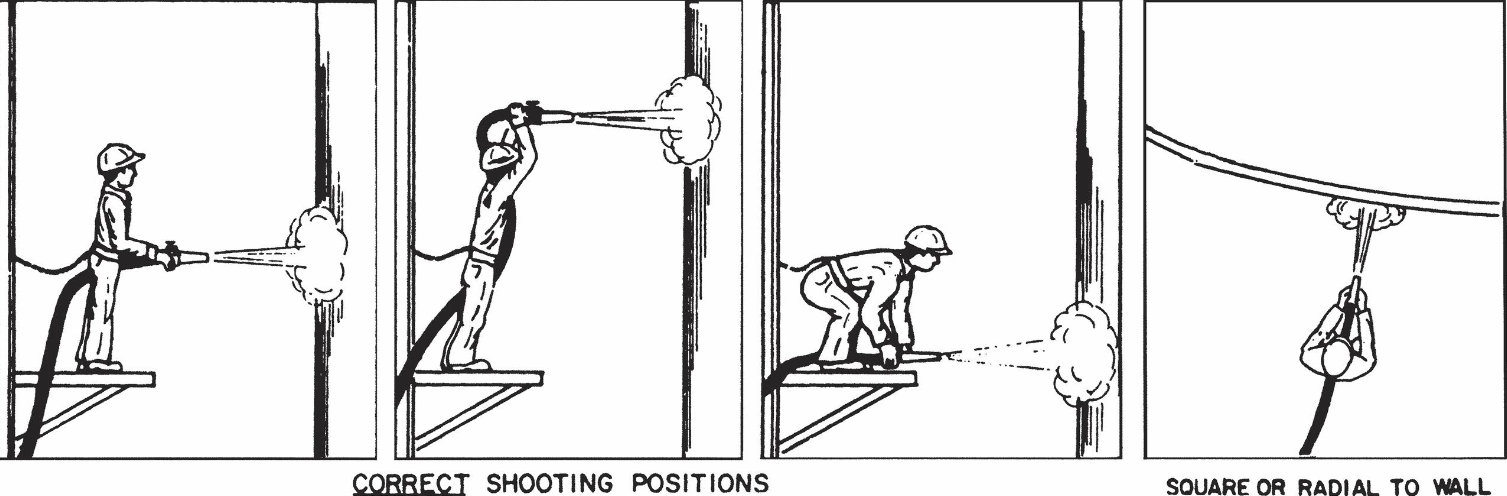

- The distance between the nozzle and the substrate should be 0.5 to 1.0 metre.

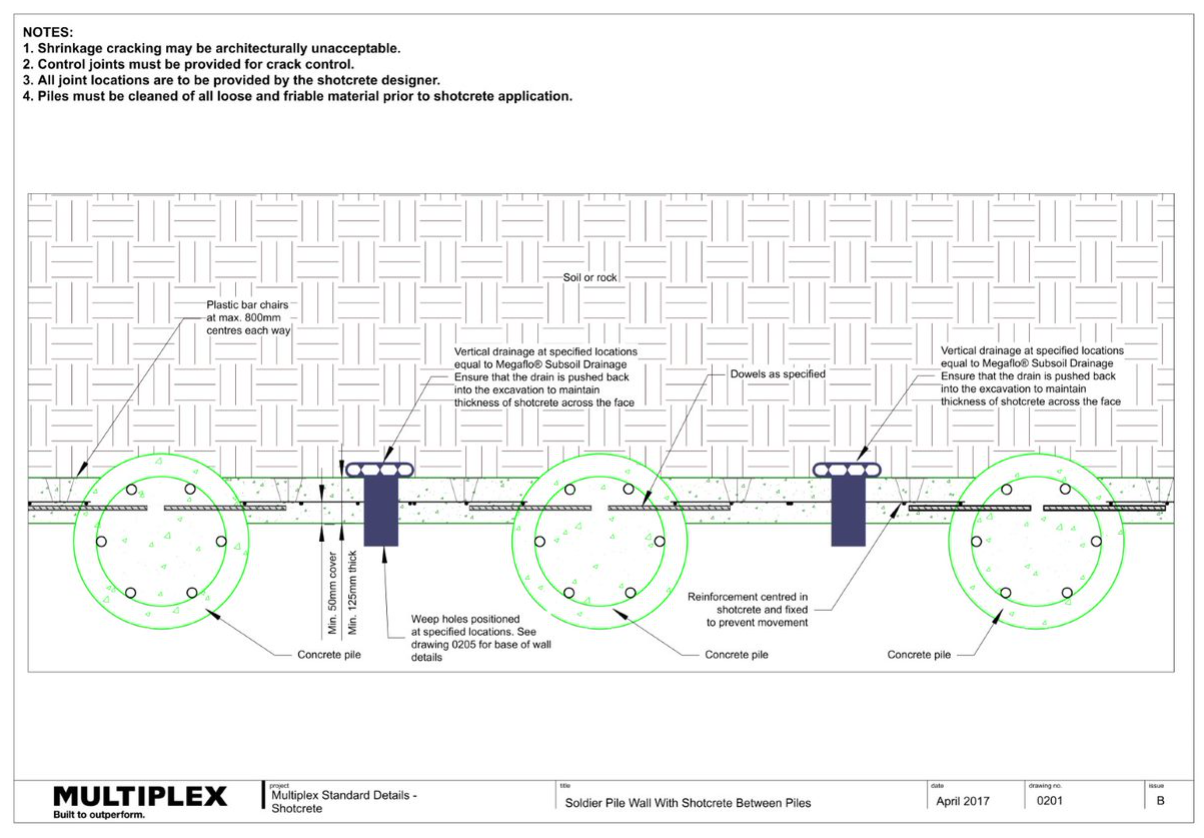

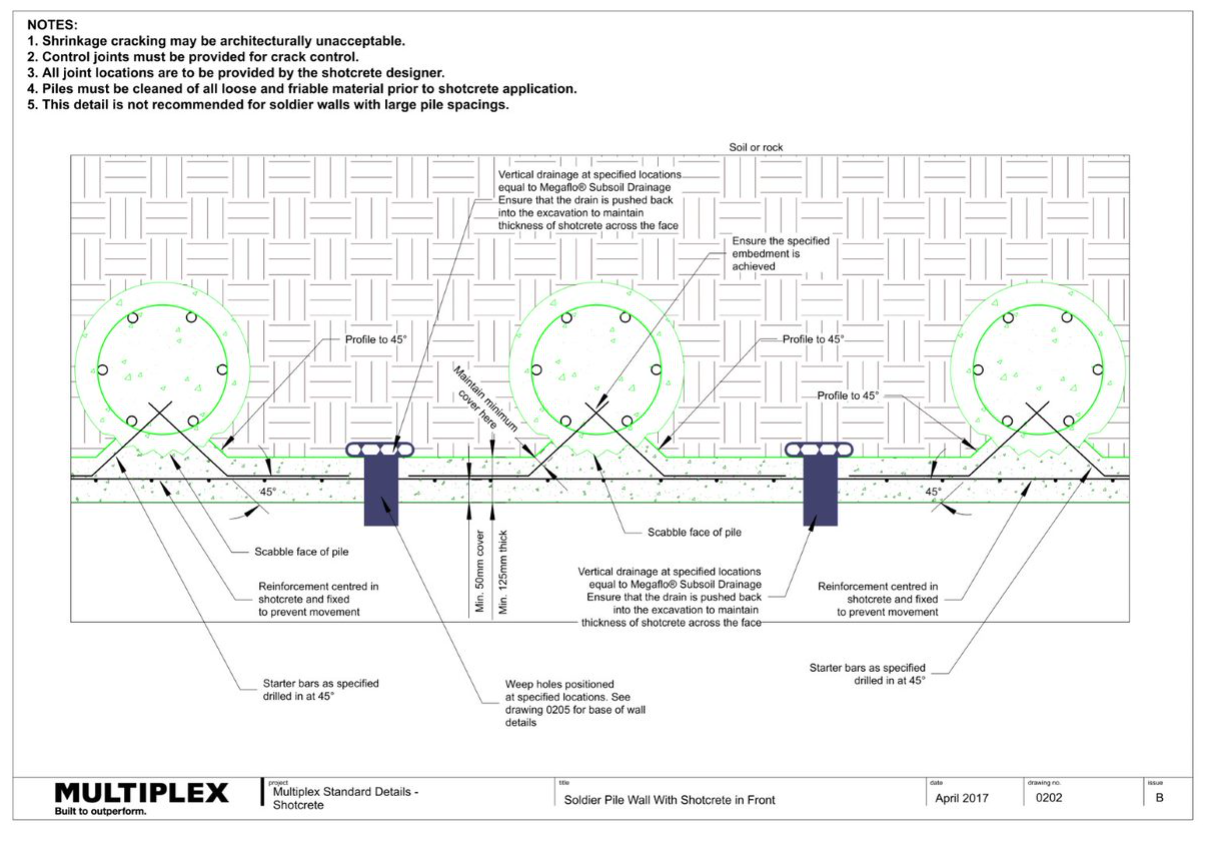

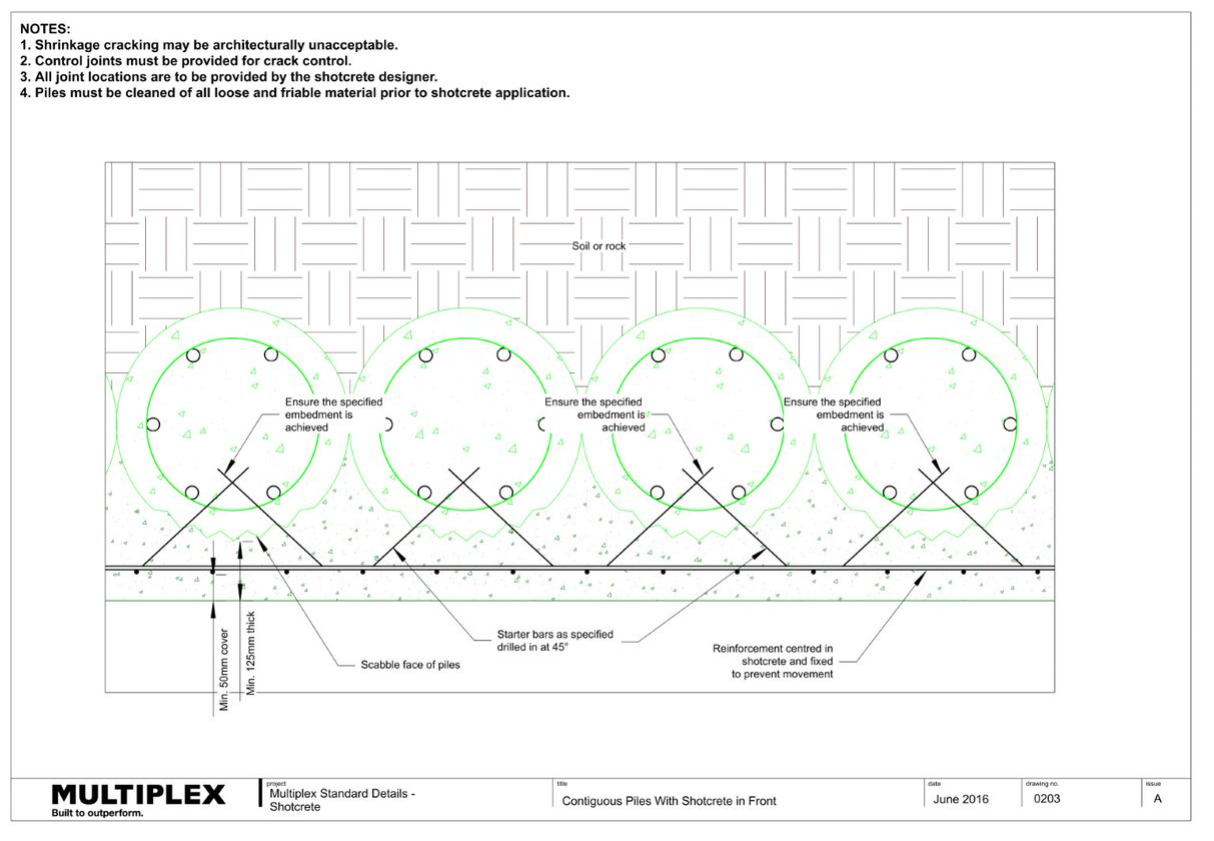

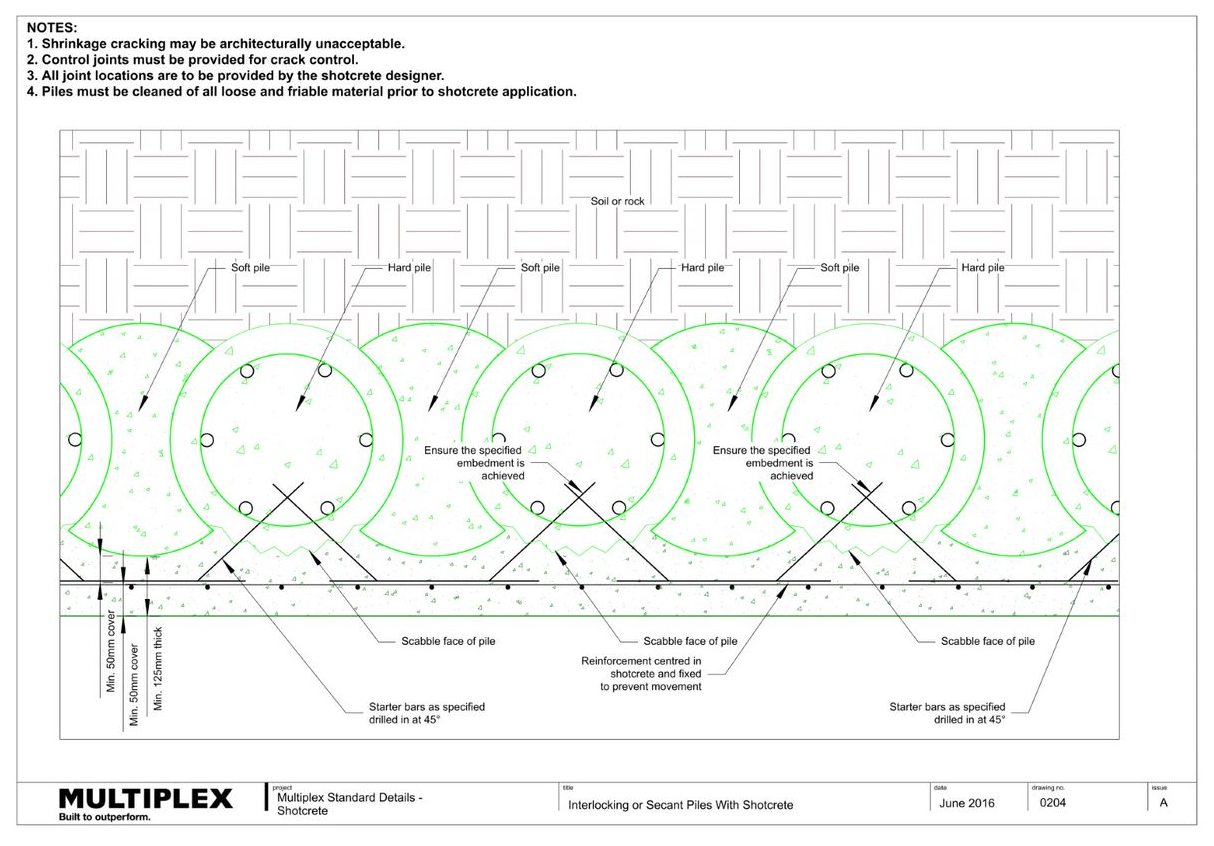

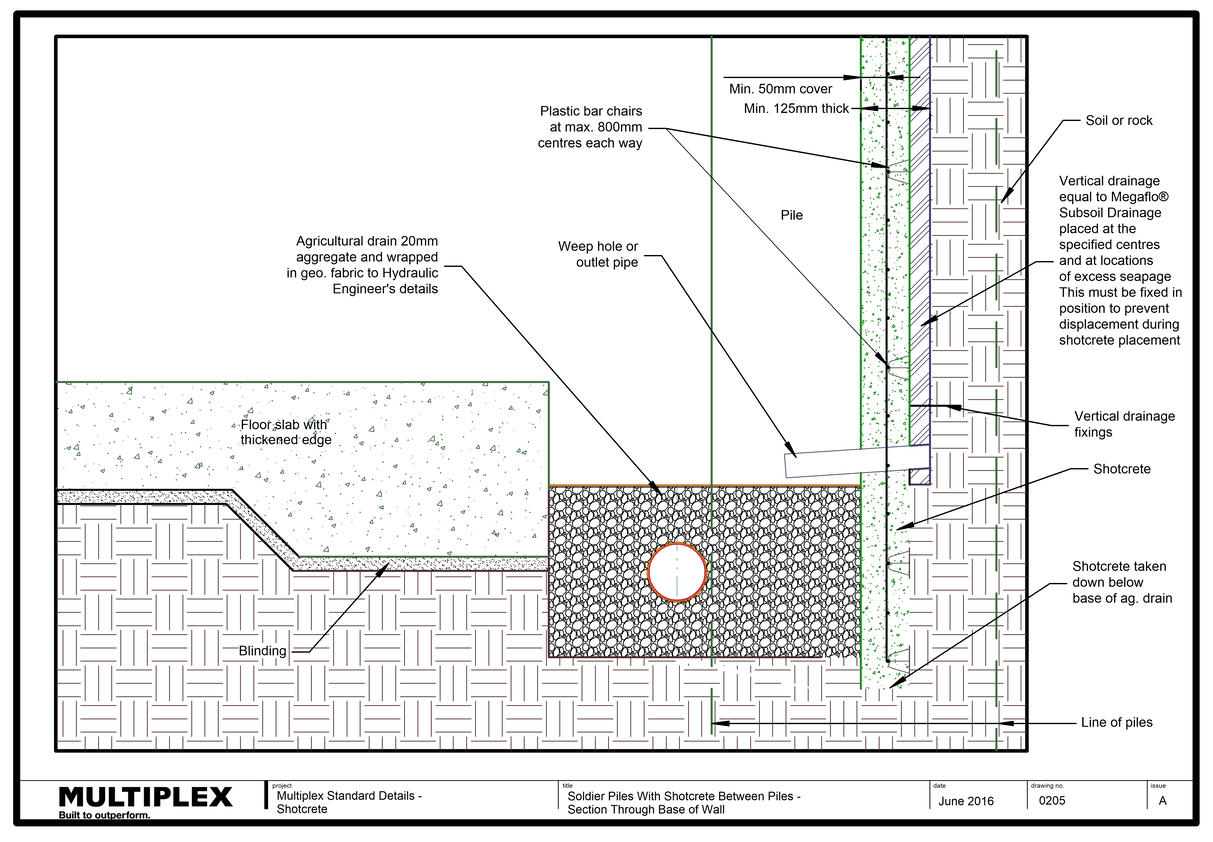

- Plastic bar chairs are installed at a max of 800mm centres in each direction.

- Cover must be:

- Minimum 50mm from shotcrete face or as specified

- Minimum 125mm cover from the ground surface or as specified

- Vertical drainage is pushed back into the excavation to maintain thickness of shotcrete across the face.

- Weep holes are installed in the specified location

Cracking

- At the completion of the curing period, the shotcrete must have no cracks of width greater than 0.15 mm, measured at the shotcrete surface or as specified by the structural engineer.

- Where such cracks exist, identify them as nonconforming.

- If repairs are required, the structural engineer must provide a specification.

Document Control

Version 2.1, April 2021