Concrete Masonry

Key Considerations

- Compartmentation Plans - Fire & Smoke

- Fire Resistance Level (FRL)

- Element Material FRL (i.e. wall, floor, ceiling)

- Service Material FRL (i.e. penetrating a compartment, FRL)

- Fire/smoke stopping system (as per MPX schedule)

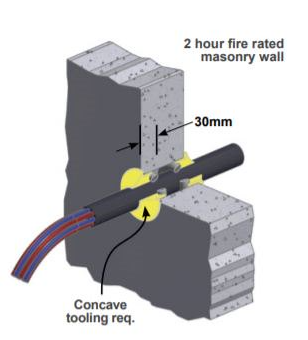

Blocks and Joints

Blocks

- Blocks must be:

- As per the approved samples.

- 2 hour rated block - 30mm wall thickness

- 4 hour rated block - 60mm wall thickness

- Installed in accordance with section Concrete Masonry (Blockwork)

Control Joints

- Fire rated sealant and backing rod must be applied at head of walls and at all control joints.

- Control joints must be installed as per Architectural and Structural Engineer’s drawings.

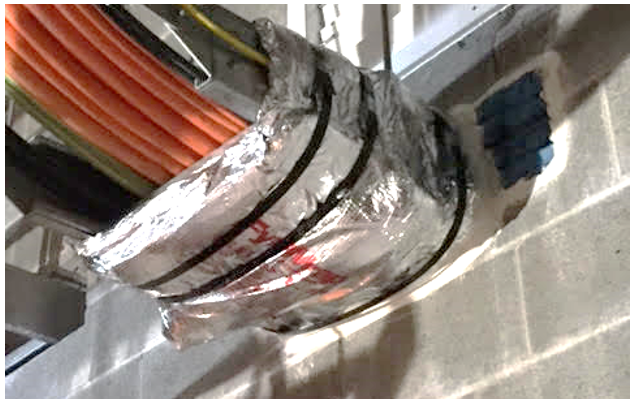

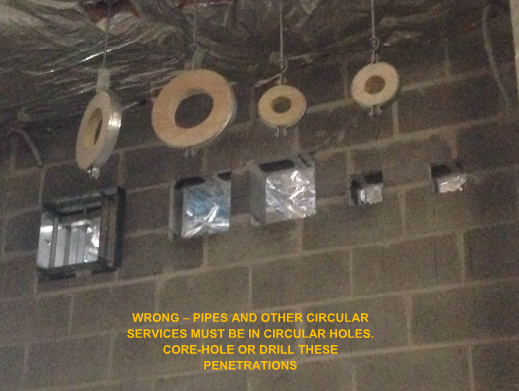

Penetrations

Blockwork (Structural Adequacy)

- Circular penetrations must be cored or drilled to ensure consistent annular gap is maintained for fire sealant application.

- Penetrations greater than 400mm must have a lintel/bond beam with drawings signed off by the Structural Engineer.

- Service penetrations must be coordinated with wall structural support systems such as wall stiffeners.

Cable Penetrations

Single Cable

Single cables must be:

- Installed in accordance with the evidence of suitability which should:

- Have a 50mm separation between any other penetration

- Be sealed with a sealant that has been tested with the specific cable type and sealed to the correct depth from both sides of the wall.

- Have a uniform annular gap (Note max and min gap) as detailed in the sealant’s fire test reports.

Bundled Cables

Bundled cables must be:

- Installed in accordance with the evidence of suitability which should:

- Have a 50mm separation between any other penetration

- Be sealed with a sealant that is tested to AS1530.4-2014 with the same cable/bundle sizes.

- Installed with the maximum size of bundled cables considered

- Be fixed with steel fasteners (surface mounted collars only).Note that fire collars are usually intended for conduits/pipes, not cables. Check test reports prior to use to ensure that the product is suitable for use with the specific cable types and other requirements

- Note: Cables above a certain size will required additional thermal wrapping to maintain the insulation rating of the penetration

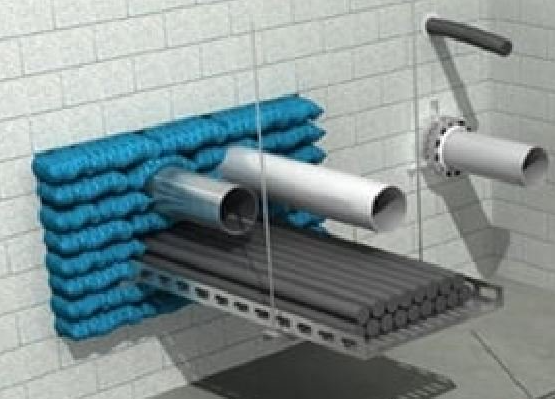

Cables on Trays

Cable trays must be:

- Installed in accordance with the evidence of suitability which should:

- Have hangers installed 150mm maximum from either side of the wall.

- Be wrapped either side to maintain insulation criteria using a wrap that is tested with the correct sealant, batt, pillow, board that has been used to seal the cables at the wall for integrity.

Conduits

Conduits must be:

- Installed in accordance with the evidence of suitability which should:

- Have either an intumescent sealant or fire collar fixed with steel fasteners

- Smoke sealed internally when passing through 2 compartments or more

- Have a separation between any other penetration.

Note: size limitations may apply to some fire stopping systems:

- Promat Conduit Collar = Max. 32mm conduit.

- Trafalgar Fyrechoke Collars = Max. 40 mm conduit

Hydraulic Pipework

Combustible ie. PVC

Combustible pipework must be:

- Installed in accordance with the evidence of suitability which should:

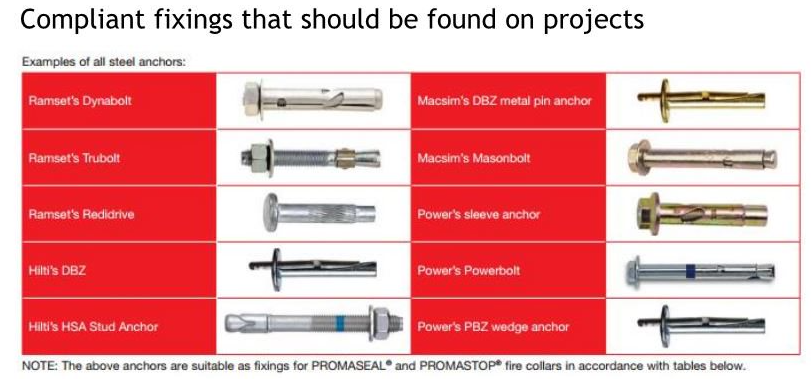

- Be installed with a retrofit collar or through collar (in wall-type) as per evidence of suitability with steel fixings / anchors.

- Have a 10-15mm annular gap

- Be sealed using a sealant that has been tested as part of the collar system when required.

- Have a separation between any other penetration as specified by the collar’s fire testing approvals.

Non-Combustible i.e. Copper

Non-combustible pipework must be:

- Installed in accordance with the evidence of suitability which should:

- Be wrapped with insulation from the surface of the wall to maintain FRL insulation criteria. Refer to the test reports for correct length of wrap based on the pipe diameters. This is required on both sides of a wall penetration, so provision of access should be considered.

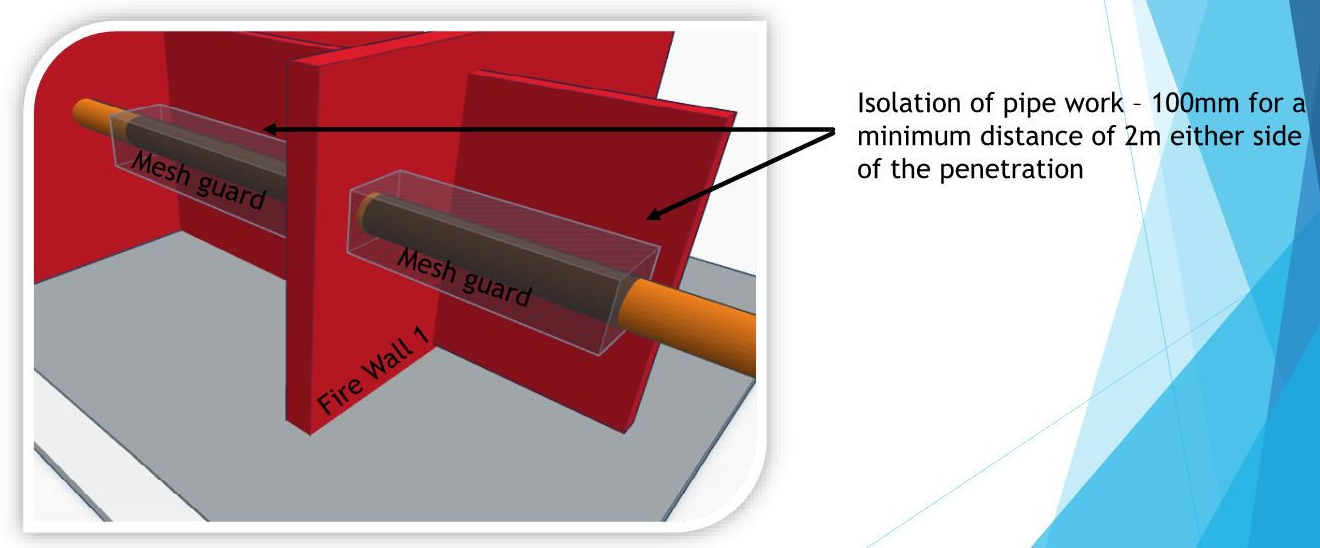

- Have a minimum 100mm clearance around the pipe from any combustible material for a length of 2m vertically (refer Figure) where required noting it is not required if using thermal insulation wrap.

- Be wrapped with insulation though the wall for chilled or hot water pipe to maintain insulation criteria, as long as the lagging is supported by a fire test or assessment report.

- Be sealed with a fire tested/assessed system.

- Have a separation between any other penetration.

Fire Dampers

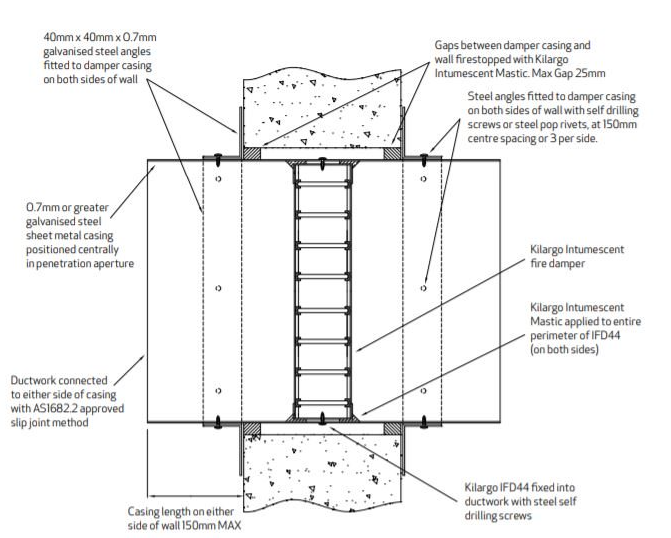

Fire dampers must be:

- Installed in accordance with the evidence of suitability which should:

- Have a separation between any other penetration.

- Installed as per section Fire Dampers.

Document Control

June 2024 – General updates relating to cables, cable trays and non-combustible pipework