Rigid Duct

General

All duct construction details must be approved by the Mechanical Consultant.

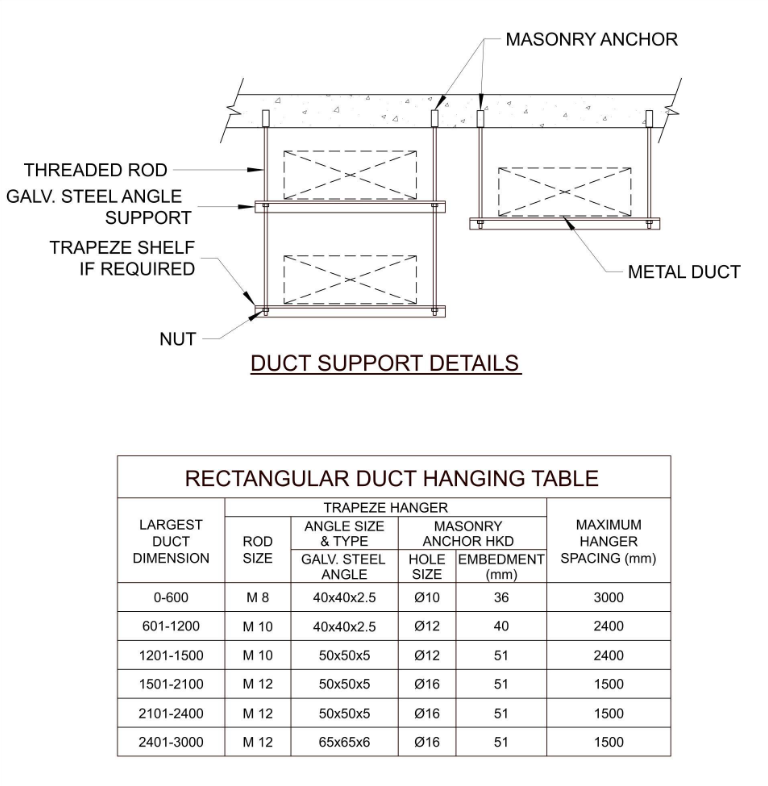

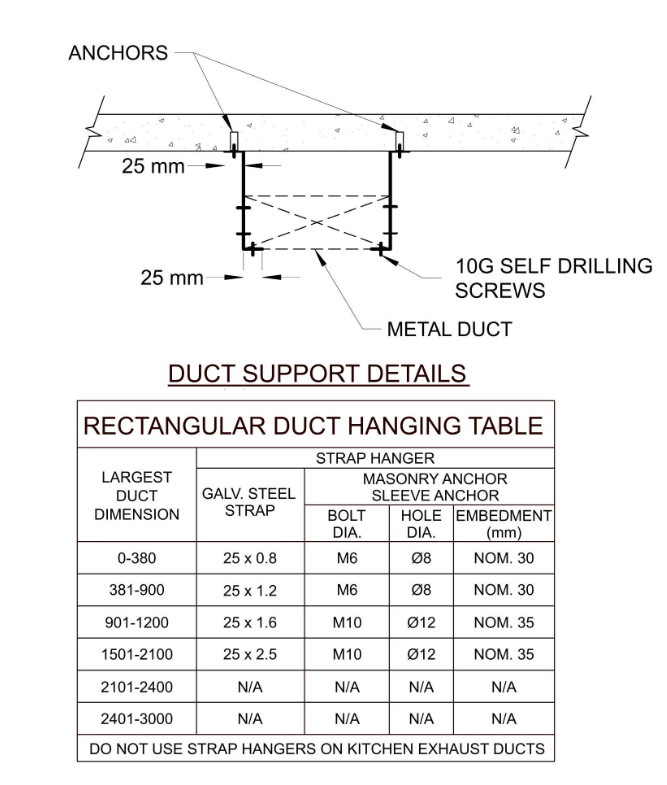

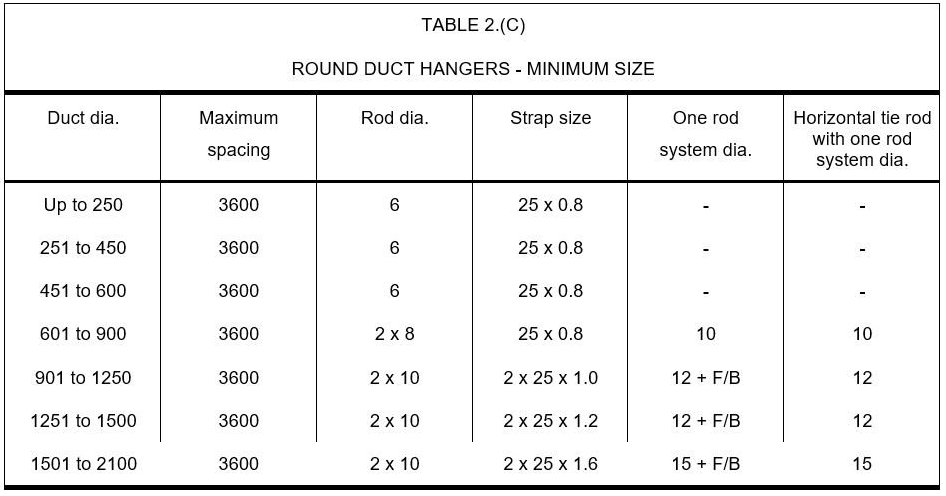

Supports

Straps and rods

- Strap and rod hanging and support systems in accordance with Clause 2.6.1 of AS4254.2 for rectangular and round duct, air terminals and air-handling plant must be:

- Installed as per approved ductwork installation and manufacturer details submitted by the subcontractor (refer examples below).

- Bolted or screwed or attached to the supporting structure in such a manner as to maintain the load-carrying capacity of the hanger.

- Straps must be fixed to the underside of the duct.

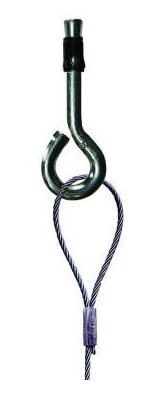

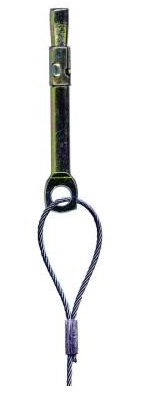

Wire rope suspension systems

- Wire rope suspension hangers and supports in accordance with Clause 2.6.2 of AS4254.2 for rectangular and round duct, air terminals and air-handling plant must be:

- Installed in accordance with manufacturers’ specifications

- Must be supplied as a matched and load-tested system

- Comprise multi-strand wire rope of galvanized or stainless-steel material

- Include an integrated end-fixing that provides attachment to the building fabric, duct, or suspension lugs provided on an air terminal or air-handling plant.

- Manufacturer and safe working load, in kilograms (kg) shall be legibly and permanently marked on each suspension system locking device.

- Where ‘essential services’ or ‘fire-rated duct’, as defined in the NCC, are required by the NCC to be fire-rated, the wire rope suspension system shall have the same fire rating as the suspended ‘essential services’ or ‘fire-rated duct’.

- Fixed to the structure, substructure (e.g. Unistrut) or a catenary, not other services.

- Hung vertically unless part of a seismic restraint system.

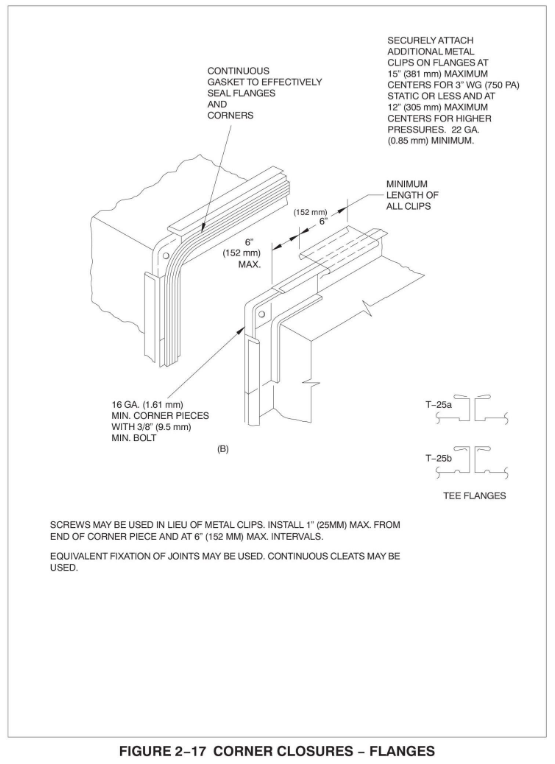

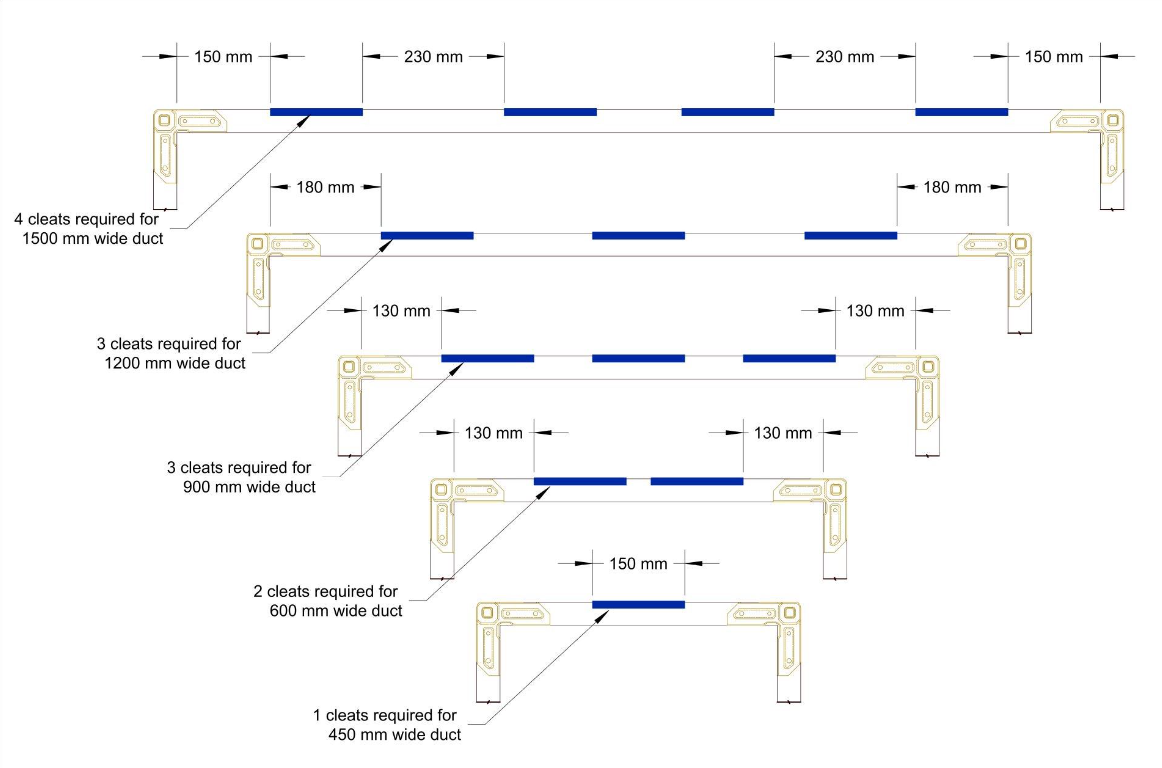

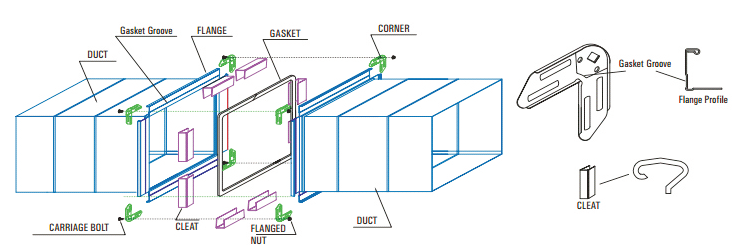

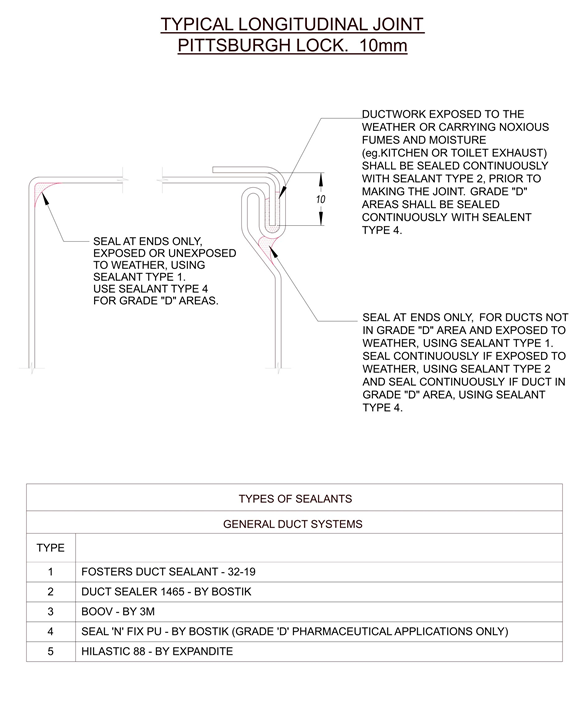

Ductwork Joints

- Ductwork joints must:

- Be installed as per approved ductwork installation and manufacturer details submitted by the subcontractor

- Have the required slides, angles and number of cleats/clips (where used) installed as per diagram below

- Be inspected by Multiplex prior to insulation and risers being closed.

Ductwork Connection Sealing

- Joints and seams of ductwork must be:

- Sealed, and

- Inspected by Multiplex prior to insulation being installed.

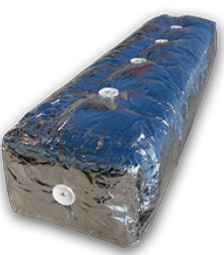

Duct Insulation

- External duct insulation must be installed:

- After the hanging system is attached and inspected by Multiplex

- With hangers, straps or fasteners that do not to compress the insulation

- In accordance with the manufacturer’s instructions

- With vapour seals (where required) that are continuous and any tears patched/taped up

- With an approved method which may include:

- Straps, or

- Mechanical fasteners (fixing pins)

- At 75mm from transverse joints and at:

- For horizontal ducts above 600 mm hold the insulation in position on the underside by means of fixing pins spaced at 400 mm maximum centres with a minimum, of one row.

- For vertical duct above 600 mm and above provide pins to all sides at maximum of 400 mm centres.

[1] Copied from TICA Qld Standard Specification Thermal and Acoustic Insulation.

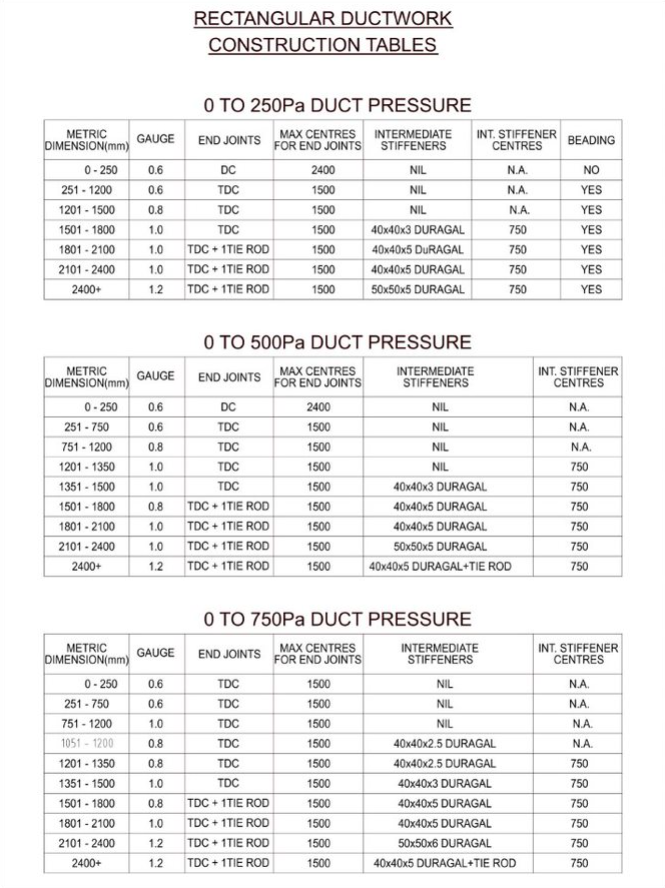

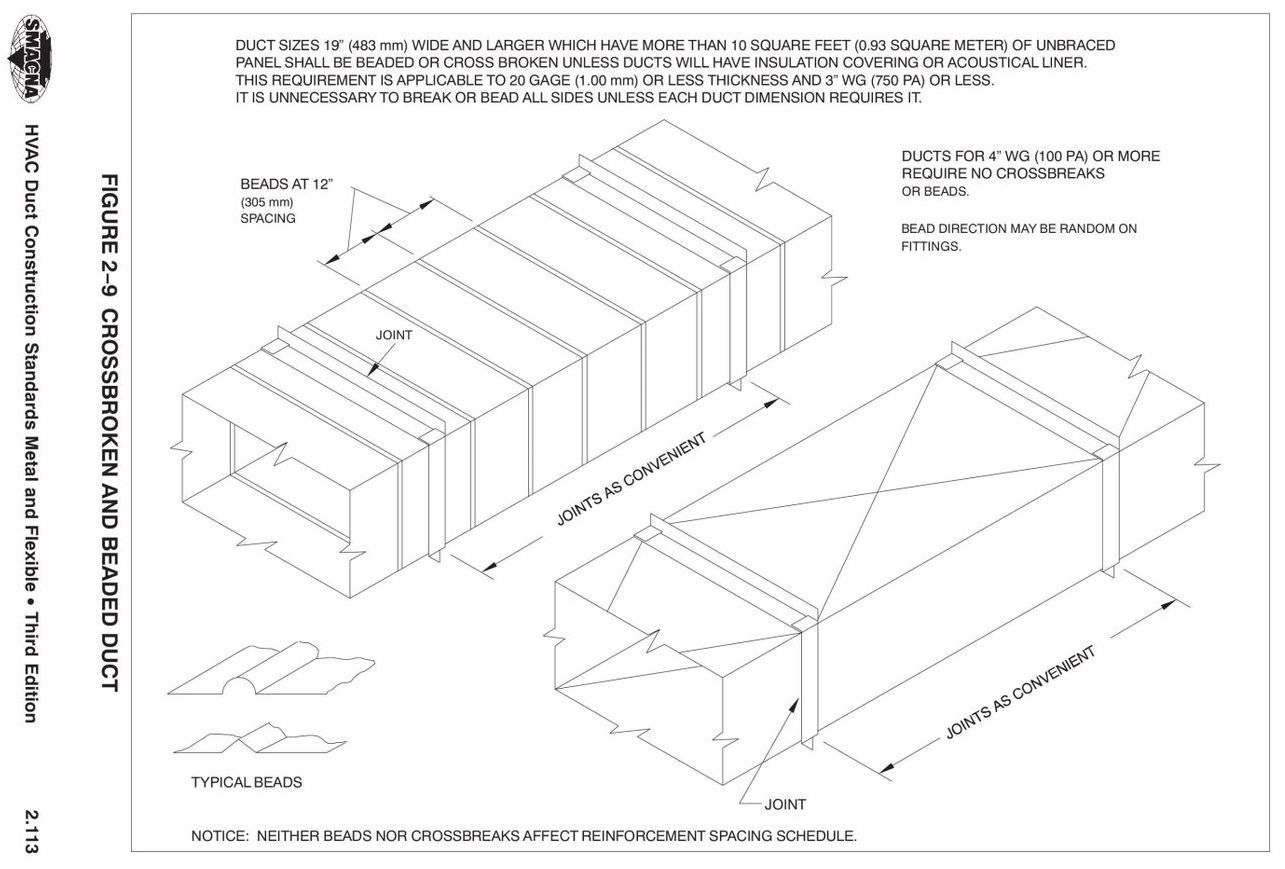

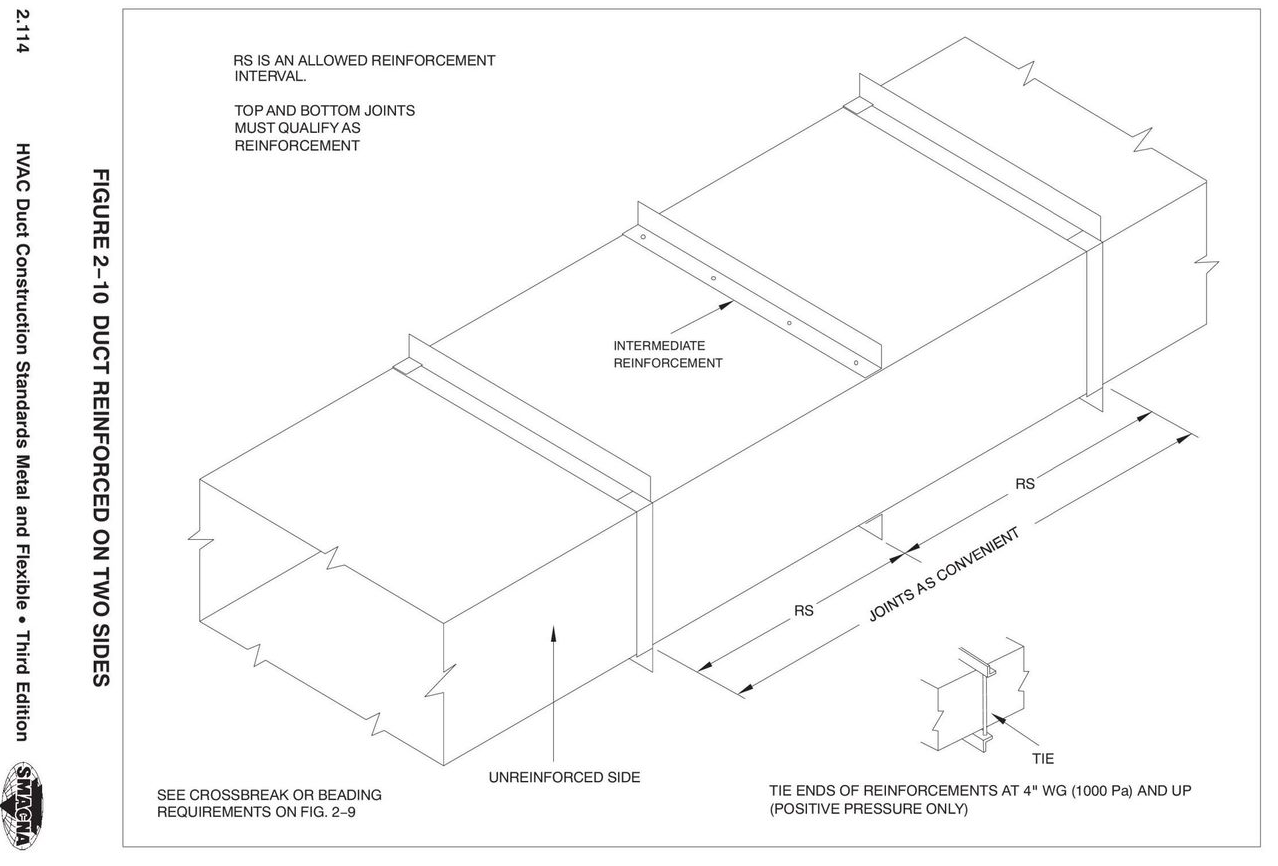

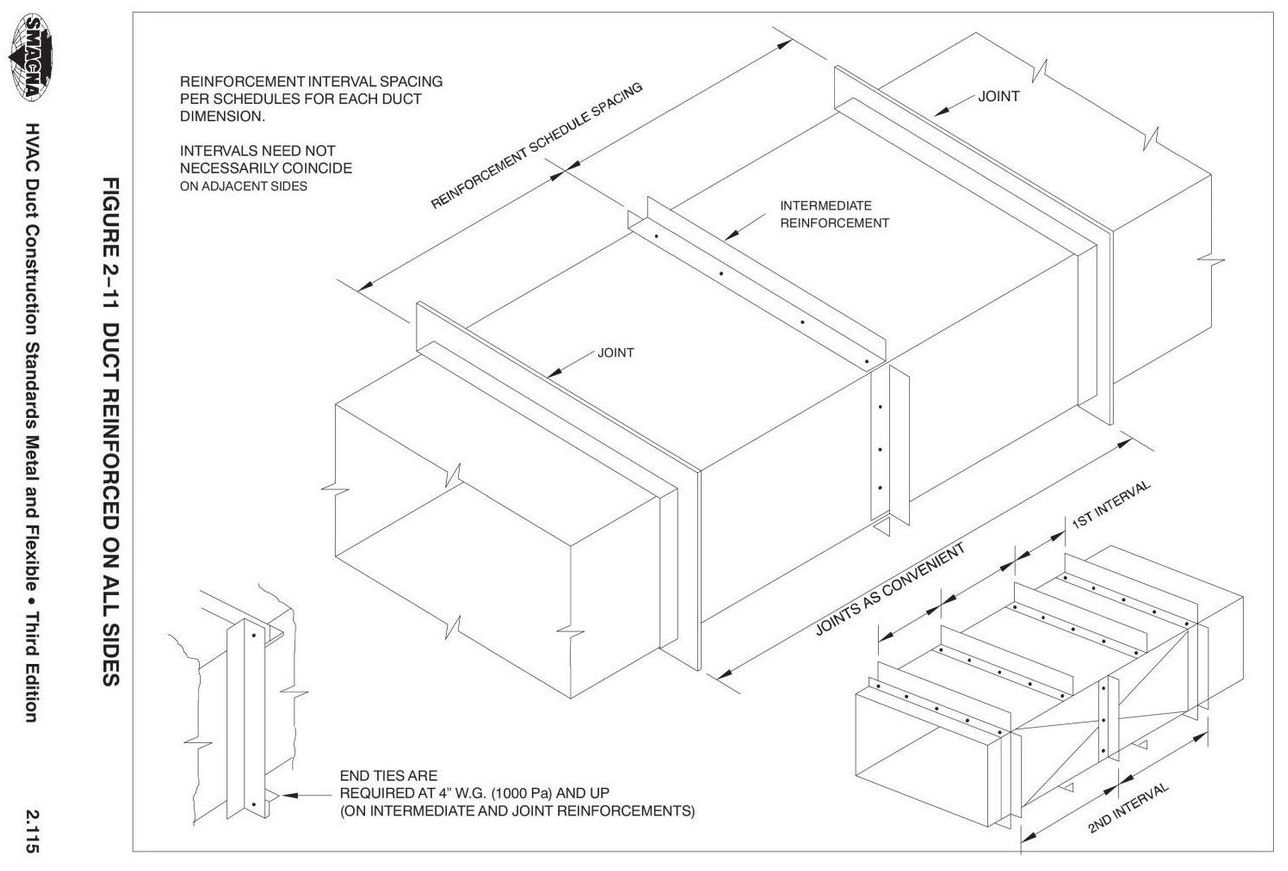

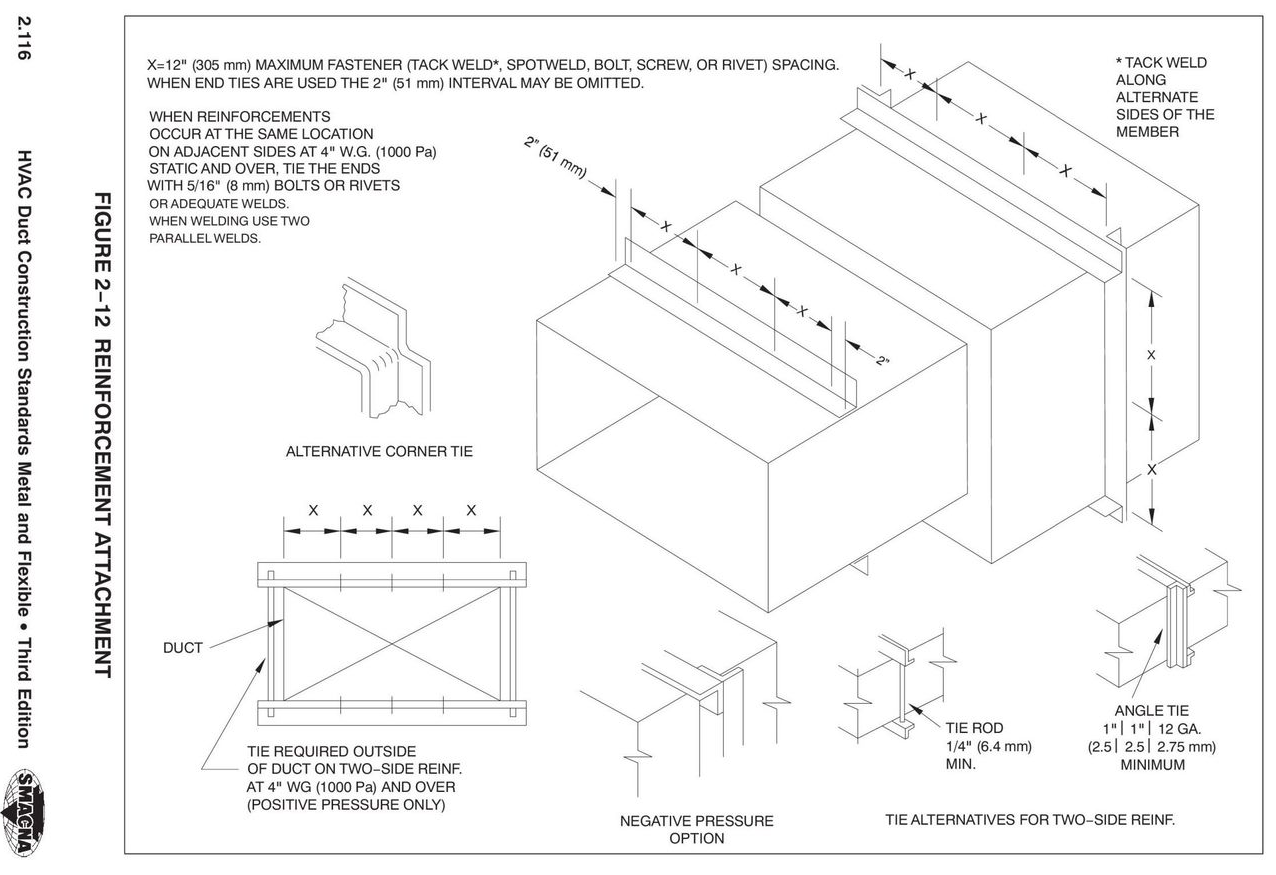

Duct Beading, Stiffening and Reinforcement

- Rectangular ducts in accordance with Clause 2.3 of AS 4254.2 must be constructed in accordance with the approved ductwork installation and manufacturer details submitted by the subcontractor (refer examples below).

General Installation

- Other services are not to be supported on ductwork supports unless approved by the mechanical subcontractor.

- Ductwork must be:

- Installed without touching other ducts, pipes, trays or hangers or any other infrastructure.

- Neatly set out, level and parallel with walls/other services.

Temporary Protection

- All ductwork must have:

- Protection with end covers when brought to site

- End covers in place until the next section of duct is attached

- End covers removed when the next section of duct is attached

- Internal duct labels removed.