Concrete Floors

Key Considerations

- Compartmentation Plans - Fire & Smoke

- Fire Resistance Level (FRL)

- Element Material FRL (i.e. wall, floor, ceiling)

- Service Material FRL (i.e. penetrating a compartment, FRL)

- Fire/smoke stopping system (as per MPX schedule)

Penetrations

What is a fire collar?

A fire collar is a type of fire-resistant fitting that maintains the integrity and fire insulation rating of a building element which has been penetrated by building services.

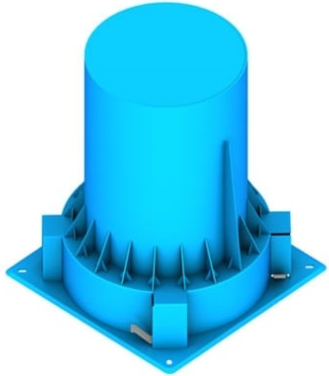

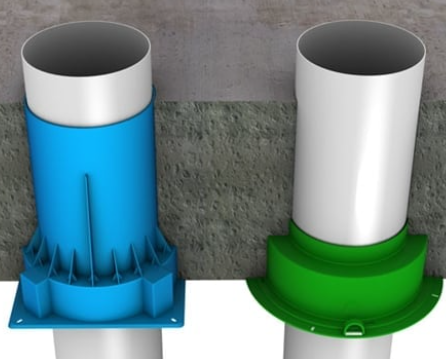

Cast in collars that are placed in position before concrete is poured/applied:

- on the timber or steel formwork of concrete slabs, finishing flush with the slab or protrude slightly above the finished slab

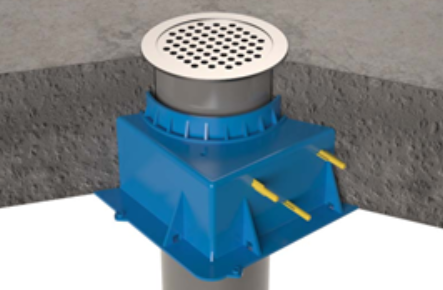

Retrofit collars that clip around existing pipes and are installed:

- on the underside of slabs

- on either side of walls

Insert slab retro fit

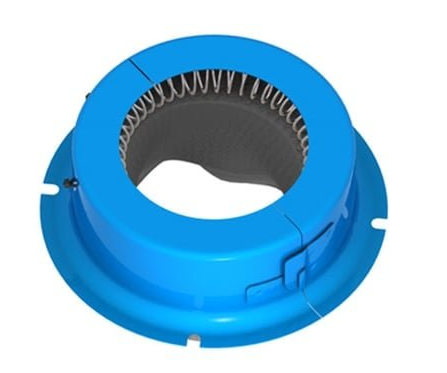

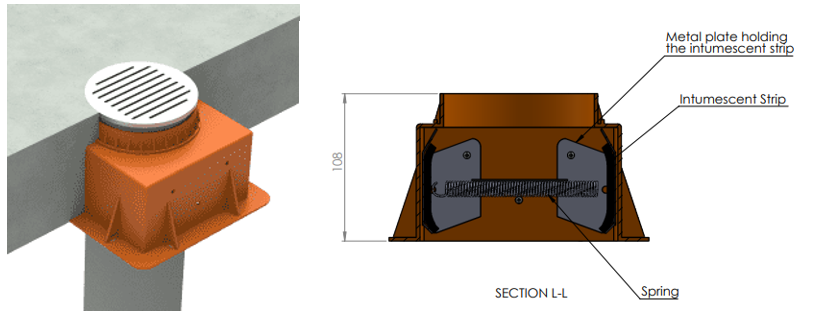

What is the difference between a floor collar and a stack collar?

Floor waste collars are required to close in a shorter duration than stack collars and thus generally have springs or other mechanisms to assist in faster closing time.

Importantly, a floor waste collar must be fire tested with a floor grate and a water trap/gully. Standard intumescent based ‘stack’ pipe fire collars must not be used on floor waste.

Why is a fire collar required?

Fire collars are required when fire walls or floors are penetrated by cables or plastic pipework. In this situation, the fire rating of the wall or floor can be reduced by the penetration as it can provide a path that allows the fire to spread beyond the compartmentation that has been designed to contain it.

Fire collars contain an intumescent material that expands and seals against flames, smoke and hot gases when plastic piping melts, thereby ensuring fire resistant integrity for the required period.

Hydraulic Pipework

Combustible ie PVC

Combustible pipework must be:

- Installed in accordance with the evidence of suitability (a fire test or assessment report to AS1530.4)

- Installed with a collar

Collars must:

- Be as per the approved sample .

- Sealed to the formwork.

- Have a min of separation from the edge of any other penetration as per structural engineer's details

- Ensure that the concrete slurry does not leach into the collar or spring pockets.

- Ensure the hole for the penetration is cut correctly to allow the mechanism to function where metal formwork systems have been used,

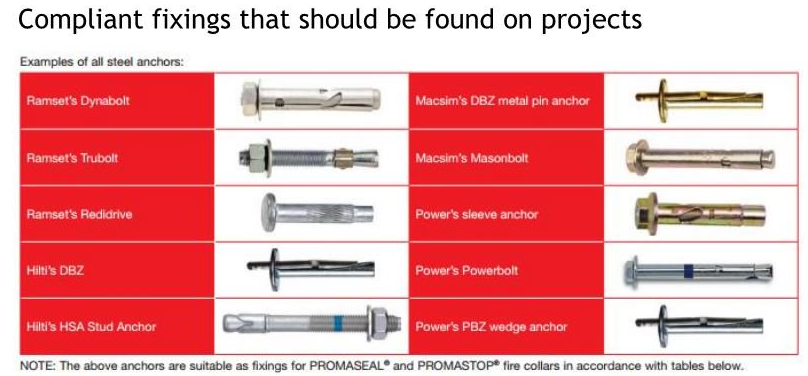

- Be installed with steel fixings / anchors if retro fitted.

Non-Combustible i.e. Copper

Fire collars are traditionally not use for non-combustible pipework, however if they are they must be:

- Installed in accordance with the evidence of suitability which should:

- Be tested for use with the correct size pipe.

- Be sealed as per the fire test reports.

- Have a min of separation from the edge of any other penetration as per structural engineer’s details.

Cable Trays

Cable trays must be:

- Installed in accordance with the evidence of suitability which should:

- Be filled with pillows, batts or equivalent

- Be sealed

- Be wrapped for a length of 2 metres from the top of the slab to maintain insulation criteria

- Have a min of separation from the edge of any other penetration as per structural engineers details.

Conduits

Conduits must be:

- Installed in accordance with the evidence of suitability which should:

- Have either a intumescent sealant or fire collar fixed with steel fasteners.

- Be smoke sealed internally when passing through 2 compartments or more.

- Have a min of separation from the edge of any other penetration as per structural engineers details.

- Have been tested or assessed with the same type of plastic conduit and size to suit the collar.

Note: size limitations may apply to some fire stopping systems:

- Promat Conduit Collar = Max. 32mm conduit.

- Trafalgar Fyrechoke Collars = Max. 40 mm conduit.

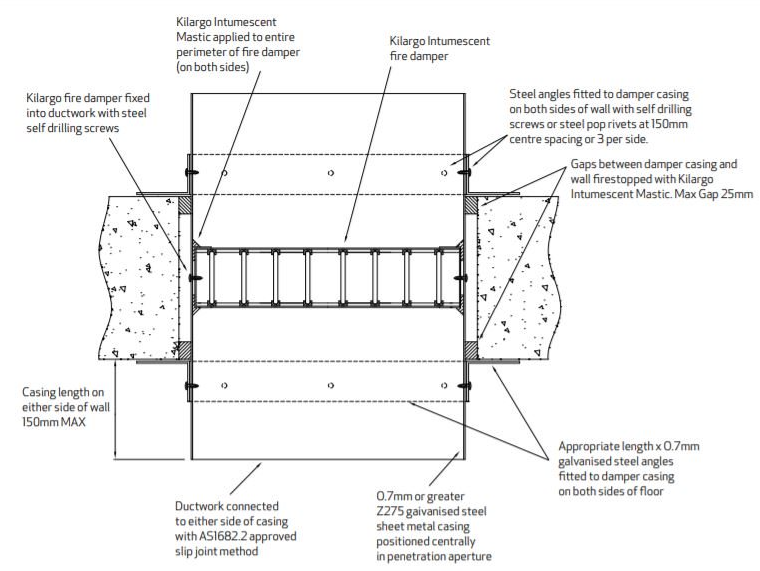

Fire Dampers

Fire dampers must be:

- Installed in accordance with the evidence of suitability which should:

- Have a min of separation from the edge of any other penetration as per structural engineers details.

- When at the top of as shaft, be insulated for a length of 2 metres from the top of the slab or be built into a masonry shaft of not less than 2000 mm high to prevent combustion of materials above and near the damper.

- Be installed as per section Fire Dampers.

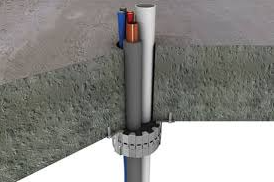

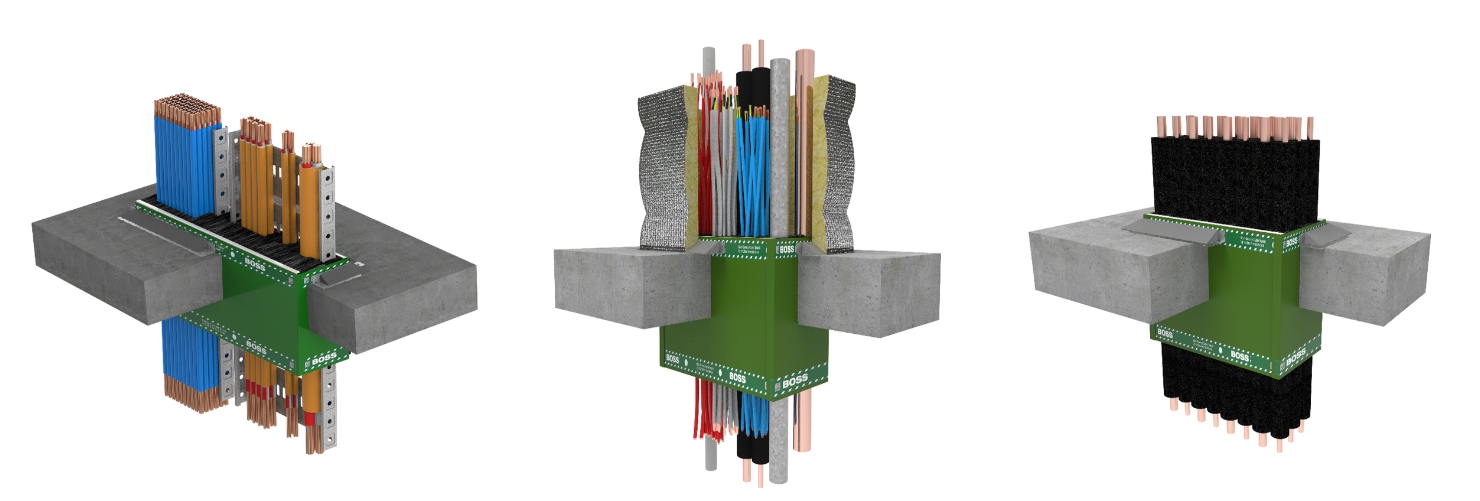

Multi-Services

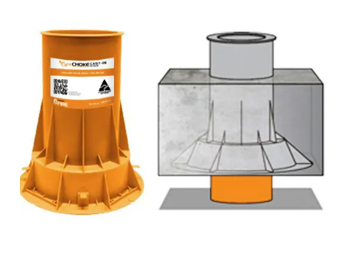

Multi-services through one penetration utilising products such as Trafalgar Cast-in FyreBOX, or Trafalgar FyreBOX Maxi/Mini must must:

- Be installed in accordance with the manufacturers installation details.

- Tested for use with the correct size and type of services.

- Incorporate smoke and acoustic (when required) seals when connecting 2 or more compartments.

Document Control

June 2024 – General updates relating to conduits and multi services.