Pedestal Paving

Key Considerations

- Material Selection

- Unit strength

- Pedestal centres

Design and Planning

- Pavers or flags must:

- Be 30mm thick or greater, and

- Tested in accordance with the specialist consultant requirements (i.e. impact, static, porosity and modulus of rupture)

- Have a marking to indicate floor waste location

- Consider design for uplift

- Engage a specialist consultant who may be the Stone Consultant

- Review capacity to drain storm events via joints

- A registered structural engineer is to be engaged to review the system holistically in accordance with AS1170 to produce the following forms within the relevant state.

- QLD – Building Act 1975, Building Regulation 2006, Form 15 Compliance Certificate for Building design or specification

- QLD – Building Act 1975, Building Regulation 2006, Form 16 Inspection Certificate/Aspect Certificate/QBCC Licensee Aspect Certificate.

- VIC – Building Act 1993, Building Regulations 2006 Regulation 1507: Certificate of Compliance – Design

- VIC – Building Act 1993, Building Regulation 2018 Regulation 126: Certificate of Compliance for Building Work

- Provide shop drawings. Include full plans showing paver and paver supports layout, adjacent construction and penetrations, and details of each condition of installation and attachment.

- Include data indicating compliance with performance requirements.

- Indicate points of supporting structure and other construction elements that must coordinate with paver installation.

- A Risk Workshop must be conducted to:

- Review the proposed locations in which pedestals and paver system is to be used

- Review the whole of life aspect, if the area will need to be maintained and use of machinery either during construction or in its life. For example, pedestals and paver system will not be able to be construction in areas that may need a EWP or Boom for future maintenance.

- Pedestals must not be used:

- Where heavy mobile vehicles or machines need to traverse.

- Where emergency or maintenance vehicles (EWP’s) need to access.

- In excess of 200mm in height. Where this is exceeded an additional pedestal must be installed under the centre of the paver. (VIC, QLD and NSW).

- The system shall withstand the effects of the following loads:

- Floors: Uniform load and concentrated loads.

- All Roof or Balcony Zones Uplift Pressures.

- Flags must be restrained by walls, hobs or similar on all sides.

- Stormwater outlets should be positioned wholly within the boundary of a full unit. Ensure pedestal locations do not overlap or otherwise obstruct drains.

- Overflow provision must be provided either by purpose made outlets (scuppers or spitters) or by overtopping of the surrounding structure.

- If overtopping is the selected method, ensure the height of the weir is a minimum of 20 mm below any sill or floor level opening into the building.

- Ensure runoff does not interfere with areas below if they are habitable spaces or publicly accessible.

- Waterproof membrane used below pedestal must have UV tolerance unless it can be shown the membrane will not be exposed to sunlight, either directly or by reflections off adjoining surfaces, and

- Be capable of resisting the imposed loads for the service life of the installation.

- Or, provide a load distribution system below each pedestal.

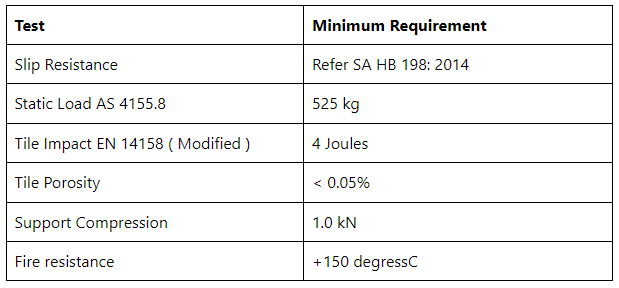

Testing

The table below outlines the suggested tests to be performed and should be reviewed in consultation with the stone consultant.

Installation

- Provide a gap to the perimeter as specified by the manufacturer to allow for thermal expansion of the flags.

- Provide a gap to any aluminium door or window frame, sill, or sub-sill.

- Allow for movement between paving and fixtures.

Flag Layout

- The Architect is to provide details of the flag joint positions.

- Consideration is required for the following: -

- Minimisation of cuts,

- Penetrating items,

- Waste locations,

- Door openings,

- Expansion joints in the structure,

- Steps or changes in heights,

- Overflow provision,

- Hobs or other restraining features.

- Requirement for TGSIs.

Expansion Joints

- Do not locate pedestals directly over expansion joints in the substrate.

- Locate pedestals on one side or the other of any expansion joint in the substrate.

Pedestal Installation

- Install pedestals to the manufacturer’s recommendations in complete rows, starting at one side of the perimeter, installing flags and adjusting to the correct level as each subsequent row of pedestals are installed.

Document Control

Version 01, December 2020 - New section detailing the requirements for pedestal paving.