Hot and Cold Pipework

Materials

- Pipework materials used for hot and cold water must be:

- In accordance with the local authority and hydraulic consultants requirements.

- Copper type B or

- PEX (Rehau or approved equivalent) or

- Stainless Steel

- Pipework made from Acrylonitrile Butadiene Styrene (ABS) or Aquatherm must not be used.

Below Ground Clearances

- Underground cold water service pipe must be separated from other services in accordance with Clause 5.2.3 of AS3500.1 (outlined in chapter 'Below Ground Separation Distances').

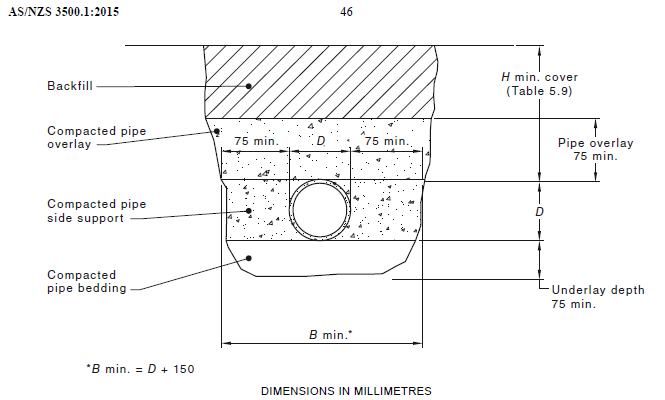

Bedding Materials

- Water services pipework installed below ground in accordance with Table 5.10 of AS3500.1 must be:

- Surrounded with not less than 75mm of compacted sand or fine-grained soil, with no hard-edged object in contact with or resting against any pipe or fitting.

- Installed with underground pipe warning tape 150mm above all underground pipes for the full length of the pipe.

Backfill

- Material used for final backfill must be free from rock, hard matter or organic material and be broken up to contain no soil lumps larger than 75mm.

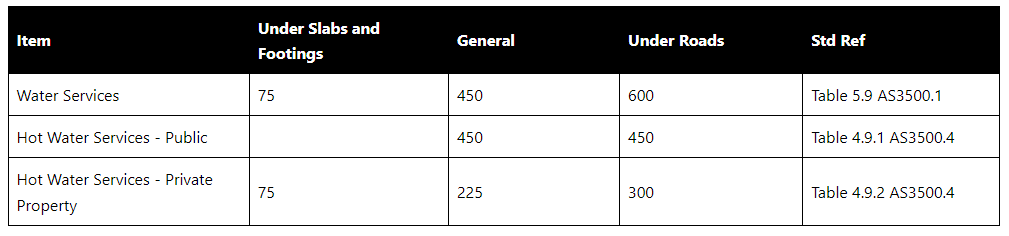

Cover

- Hot and cold water services installed below ground must have minimum depths of cover as outlined below:

Below Ground Protection

- Copper pipes in accordance with Clause 5.2 of AS4809 installed below ground must:

- Be suitably protected against external corrosion by means of pre-insulated copper pipe, petrolatum-based wrapping or equivalent.

- Have all joins wrapped with a durable inert waterproof tape.

Under Concrete

- Water service pipes laid under concrete in accordance with Clause 5.4.4 of AS3500.1 must be:

- Continuously lagged with an impermeable material

- Laid in a narrow trench on a bed of sand or fine-grained soil placed and compacted.

- A minimum distance of 75mm between the top of the pipe and the underside of the slab.

- Copper pipes laid under concrete in accordance with Clause 6.2 of AS4809 must:

- Be either Type A or Type B.

- Be continuously lagged with an impermeable material.

- Have all joins wrapped with a durable inert waterproof tape.

- Have any pipework that penetrates the slab at right angles insulated with an impermeable flexible plastic material of not less than 6 mm thickness for the full depth of the slab penetration.

Casting in Concrete

- Copper pipes must not be embedded or cast into concrete structures

- PEX pipes embedded in a concrete must be:

- Installed in an approved conduit.

- Installed with no joints in the pipe.

Above Ground Clearances

- Pipework must be separated from other services in accordance with:

- Clause 5.2.2 of AS3500.1 for cold water.

- Clause 4.2.2.2 of AS3500.4 for hot water. (Refer chapter 'Above Ground Separation Distances').

Brackets and Supports

- Cold water services in accordance with Clause 5.6 of AS3500.1 must be retained in position by brackets, clips or hangers that are:

- Securely attached to the building structure and not to any other service

- Clamped securely to prevent movement, unless designed to allow for thermal movement

- Supported and fixed at the intervals specified in Table 5.6.4. of AS 3500.1 – refer horizontal pipe support spacing and vertical pipe support spacing or manufactures specifications.

- Hot water services in accordance with Clause 4.4 of AS3500.4 must be retained in position by brackets, clips or hangers that:

- Are supported and fixed in accordance with the requirements outlined above

- Allow movement due to thermal expansion and not cause damage or corrosion to the pipe.

- Copper pipes must be supported at spacings in accordance with Table 6.2 of AS4809 which is outlined in horizontal pipe support spacing and vertical pipe support spacing.

- PEX pipes must be:

- Supported at spacings in accordance with the manufacturer’s specification

- Protected with a rubber grommet to the stud where the pipe passes through, to prevent abrasive action between the stud and the pipe.

Corrosion

- Copper pipework in accordance with Clause 5.2 of AS 4809 must be suitably protected against external corrosion by:

- Using pre-insulated copper pipe or petrolatum-based wrapping or equivalent

- Wrapping joints with a durable inert waterproof tape.

- Metallic pipes, metallic fittings or Type M multilayer copper pipes installed in a water service in corrosive areas must be protected externally in accordance with Clause 5.12 of AS3500.1:

- With an impermeable flexible plastic coating

- By placing in a sealed polyethylene sleeve or

- By continuously wrapping in a petrolatum taping material.

- NOTE: Corrosive areas are those that contain substances such as any compound consisting of magnesium oxychloride (magnesite) or its equivalent, coal wash, acid sulphate soils, sodium chloride (salt), ammonia or materials that could produce ammonia.

Expansion Joints

- Expansion joints must be provided for all pipes in all locations as outlined in AS3500.4, Clause 4.12.3, approved drawings or manufacturer’s specifications.

Testing

- Pipework must be tested for 1500kPa for 30 minutes in accordance with AS 3500.1 (cold water) and AS 3500.4 (hot water) or as per hydraulic specification whichever is greater.